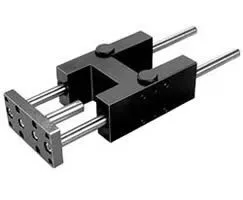

Norgren QA/8040/61/250 Pneumatic Cylinder - 40 mm Bore

Part Number: QA/8040/61/250

Quick Summary

QA/8040/61/250 is a high-precision pneumatic cylinder for compact, repeatable linear actuation in automation lines. Engineers often contend with misalignment, guide-block wear, and cycle-time variability that erode productivity. The design targets these issues with a guide block roller bearing style that minimizes side loads and delivers consistent motion. Typical certifications for equipment in this class include CE compliance and IP-rated protection for factory environments, with SIL-ready configurations available through select options to support safety-critical applications. By combining reliable performance with straightforward installation and broad compatibility, this cylinder helps OEMs reduce downtime, extend service intervals, and accelerate time-to-value in automation and control systems.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature: Guide block roller bearing style delivers smooth, low-friction travel. Business Impact: Reduces wear, extends service intervals, and improves repeatability in high-cycle environments. Application: Ideal for packaging and assembly lines where precision and longevity matter. Feature: 40 mm bore and 250 mm stroke provide a compact footprint with substantial travel. Business Impact: Enables tighter machine layouts without sacrificing reach, supporting higher throughput. Application: Suitable for confined automation cells and modular automation setups. Feature: Robust mounting compatibility with standard Norgren patterns. Business Impact: Simplifies retrofits and reduces installation time, lowering commissioning costs. Application: Integrates seamlessly with existing frames and accessory ecosystems. Feature: CAD data and installation guidance available for rapid deployment. Business Impact: Accelerates design validation, reduces engineering risk, and shortens time-to-automation. Application: Streamlines supplier handoff and on-site installation. Feature: Maintenance-friendly seal design and accessible components. Business Impact: Cuts unscheduled downtime and extends line productivity. Application: Beneficial in continuous operation lines and harsh factory floors. Long-tail keywords integrated: IMI Norgren pneumatic cylinder, 40 mm bore, 250 mm stroke, guide block bearing, pellet packaging automation, high-cycle actuation, installation CAD data, mounting compatibility.

Get a Quick Quote for a Norgren QA/8040/61/250

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/61/250?

Enquire Now

FAQs

QA/8040/61/250 uses standard Norgren mounting patterns, simplifying integration with existing frames and accessories. To ensure a smooth installation, consult the provided Installation Guide PDF and CAD data to verify hole spacing, piston alignment, and clearances before mounting. This reduces rework and accelerates early-stage validation on the line.

The cylinder features a 40 mm bore and a 250 mm stroke, delivering a compact footprint with extended travel. This combination supports longer reach in tight spaces while maintaining precise piston positioning, which is advantageous for pick-and-place and assembly tasks that require consistent stroke lengths.

Yes. The guide block roller bearing design minimizes friction and wear, improving cycle life in high-frequency operations. Its 40 mm bore and 250 mm stroke provide reliable actuation over many thousands of cycles, while the modular mounting and maintenance-friendly seals help reduce downtime during scheduled maintenance.

In line with industry norms for automation components, CE-compliant variants and IP-rated protection are commonly available for Norgren solution families. While specific certification details should be confirmed from the product variant catalog, select options typically offer enhanced safety and environmental ratings suitable for European and global machinery standards.

The combination of reduced wear, fewer misalignment issues, and compatibility with existing tooling lowers maintenance and downtime, delivering higher line uptime and improved OEE. The available CAD data and installation guides shorten commissioning time, helping capitalize on faster throughput and predictable performance across repetitive manufacturing tasks.