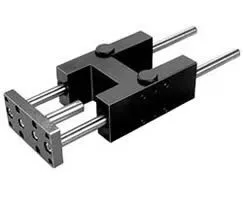

Norgren QA/8040/61/320 Guide Block - 40mm bore, 320mm stroke

Part Number: QA/8040/61/320

Quick Summary

QA/8040/61/320 is a guide block roller bearing system designed for precise linear motion in automation lines. Design engineers often wrestle with misalignment and wear in compact pneumatic cylinders, which drives maintenance costs and downtime. In practical terms, CE marking for safety compliance, IP-rated options for rugged environments, and SIL-compatible safety integration are important considerations when selecting a guide block. By pairing the QA/8040/61/320 with standard mounting interfaces and compatible guides, you can simplify installation and ensure reliable performance across varying cycle times. This approach supports faster development cycles and better total cost of ownership, while leveraging Norgren’s precision engineering and strong aftersales support.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature: 40 mm bore pneumatic cylinder. Business Impact: Delivers compact form factor with sufficient thrust for medium-duty tasks, enabling tighter machine layouts and lower actuation energy. Application: Ideal for pick-and-place and transfer stages in packaging lines where space is at a premium and cycle times are moderate. Feature: 320 mm stroke. Business Impact: Extends travel distance per actuator, reducing the number of components required for longer transfer paths and simplifying control logic. Application: Useful in automated assembly or sorting stations where longer strokes improve throughput. Feature: Guide block roller bearing style. Business Impact: Minimizes side loads and wear, increasing travel smoothness and extending service life in high-cycle environments. Application: Critical for racking, alignment tasks, and precision positioning in robotic cells. Feature: Compatibility with standard mounting patterns and ready CAD data. Business Impact: Speeds up design-in and commissioning, cutting engineering effort and startup time. Application: Supports rapid integration with CAM workflows and vendor libraries. Feature: Installation guide and online CAD resources. Business Impact: Reduces commissioning risk and misconfiguration, lowering maintenance calls. Application: Helpful for technician onboarding and field service. This combination delivers measurable outcomes such as improved reliability, reduced maintenance costs, and better uptime for automation and control systems, while aligning with long-tail needs like 40 mm bore pneumatics, 320 mm stroke actuators, and ISO-compatible assemblies.

Get a Quick Quote for a Norgren QA/8040/61/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/61/320?

Enquire Now

FAQs

To install QA/8040/61/320, verify bore and stroke compatibility with your design, align the guide block with the rail, and secure mounting using standard ISO patterns. Use the provided CAD data and installation guide to ensure correct fastener torque and clearances, reducing misalignment and early wear during initial commissioning.

The 40 mm bore provides a balanced thrust suitable for medium-duty tasks, while the 320 mm stroke enables longer travel per actuator, decreasing the need for multiple cylinders in transfer paths. This combination supports higher cycle efficiency and simpler control logic in packaging, sorting, and assembly applications.

Yes, the QA/8040/61/320 is designed to fit standard mounting interfaces common in automation and robotics. When pairing with ISO mount rails and standard end fittings, installation is straightforward, and cross-compatibility with existing frames minimizes retrofit costs.

Key considerations include CE marking for European safety compliance and ensuring any environment-specific requirements are met, such as IP-rated enclosures or SIL-compatible safety integration when used in safety-critical lines. Always confirm the exact certifications listed in the datasheet for your regional and process requirements.

The roller-bearing guidance reduces wear, lowers side-load-induced fatigue, and minimizes downtime, translating to longer service intervals and lower maintenance costs. Combined with faster design-in via CAD resources and standard mounting, you can achieve quicker project payback and higher overall equipment effectiveness (OEE) in automated lines.