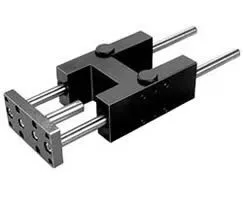

Norgren QA/8040/61/400 Guide Block - 40 mm Bore

Part Number: QA/8040/61/400

Quick Summary

Norgren QA/8040/61/400 guide block delivers precise pneumatic actuation for linear motion applications. Engineers often struggle with misalignment, wear, and downtime in slide and positioning systems. Designed to meet common industry expectations, CE marking ensures European compliance, IP-rated protection guards against dust and moisture, and SIL considerations are addressed in safety-critical integrations. This model pairs with standard Norgren components for scalable automation, enabling fast commissioning, reduced integration risk, and lower total cost of ownership in automated manufacturing environments.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The 40 mm bore provides a compact yet capable footprint, delivering a favorable power-to-weight balance for tight spaces in automotive fixtures and packaging lines. This translates to efficient use of cabinet space and lower system inertia when cycled at high frequencies. Feature → Business Impact → Application: A 400 mm stroke enables extended travel in pick-and-place conveyors and alignment fixtures, reducing the number of auxiliary actuators required and improving line throughput. Feature → Business Impact → Application: Guide block roller bearing style 61 delivers smooth motion with reduced wear, lowering maintenance intervals and ensuring repeatable positioning in high-cycle automation cells. Feature → Business Impact → Application: Compatibility with CAD models and installation guides accelerates the engineering workflow, minimizes errors, and supports rapid integration with existing Norgren ecosystems. Feature → Business Impact → Application: Standard mounting patterns and modular compatibility enable straightforward upgrades and easy retrofit in legacy lines, reducing downtime during enhancements. Feature → Business Impact → Application: Robust construction and proven sealing concepts support reliable operation in factory floors with dusty or moist environments, improving uptime and safety margins.

Get a Quick Quote for a Norgren QA/8040/61/400

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/61/400?

Enquire Now

FAQs

Yes. The QA/8040/61/400 employs standard mounting patterns and widely-used fittings typical of Norgren guide block cylinders, enabling straightforward mounting to compatible frames, fixtures, and brackets. When planning integration, verify bolt pattern, fastening torque, and compatible end fittings to ensure a seamless retrofit or new-build installation.

Core specs include a 40 mm bore and a 400 mm stroke. Guidance is provided by a roller bearing style 61 guide block for smooth, repeatable motion. These specifications support precise positioning with reliable cycle performance in compact footprints, suitable for high-cycle automation tasks.

This model is well-suited for packaging lines, automated assembly, and fixture positioning where compact geometry and long travel are required. The combination of a 40 mm bore and 400 mm stroke supports efficient space utilization in robotics cells, pick-and-place stations, and fixture-alignment tasks across manufacturing environments.

In typical European deployments, CE compliance is expected for electronic and pneumatic components. IP protection considerations address dust and moisture exposure in factory settings, while SIL considerations may apply to safety-critical integrations. Always confirm the specific certifications listed in the accompanying datasheet and installation documents for your region.

The roller-bearing guide block reduces friction and wear, extending service intervals and lowering maintenance frequency. Long travel with a compact bore minimizes the number of actuators required, reducing upfront hardware costs and simplifying spare-part inventories. Access to CAD models and installation guides speeds commissioning, cutting engineering time and accelerating time-to-value.