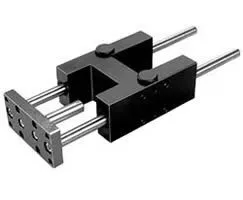

Norgren QA/8040/61/50 - 40 mm Bore, 50 mm Stroke

Part Number: QA/8040/61/50

Quick Summary

Norgren QA/8040/61/50 is a guide block roller bearing style pneumatic actuator designed for precise linear motion in compact automation applications. Engineers often contend with misalignment, friction, and wear in tight spaces, which can degrade cycle times and elevate maintenance costs. CE compliance and IP-rated configurations are common in factory automation, offering safety and reliability in harsh environments. For procurement and integration teams, the combination of a compact footprint, accessible CAD data, and a practical installation guide enables faster deployment and reduced project risk while delivering consistent performance in automated systems.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

The 40 mm bore and 50 mm stroke with a guide block roller bearing style 61 deliver precise actuation within a compact envelope, reducing side loads and improving repeatability. This directly translates to shorter setup times, fewer misfeeds, and lower maintenance overhead in conveyor and indexing applications. The design supports smoother, steadier travel, which translates to improved cycle stability and higher overall equipment effectiveness in automated lines. Compatibility with standard mounting patterns and the availability of CAD data and an Installation Guide streamline integration, decreasing engineering time and accelerating time-to-value for new lines and retrofits. Durable construction and rolling-contact guidance minimize wear, extending service intervals and reducing replacement costs in high-cycle environments. The actuator’s compact footprint also enables easier integration in crowded control cabinets and tight machine cells, supporting lean manufacturing initiatives and cost-efficient upgrades. Industry professionals benefit from the combination of predictable performance, straightforward installation, and reliable operation in demanding automation tasks such as pick-and-place, dosing, and precise positioning.

Get a Quick Quote for a Norgren QA/8040/61/50

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/61/50?

Enquire Now

FAQs

When installing the QA/8040/61/50, start by reviewing the Installation Guide to confirm mounting orientation and alignment. Use the CAD resources to verify shareable mounting patterns and ensure compatibility with your existing bracketry. Check for proper support at the bore to minimize side loads, and verify that the 50 mm stroke range accommodates your travel path without overextension. Confirm fastener accessibility and avoid over-tightening to preserve smooth operation.

The 40 mm bore provides an adequate actuating force for typical pick-and-place and indexing tasks, while the 50 mm stroke offers a practical travel range for compact machinery. Together, they enable precise positioning with repeatable cycles and reduce cycle time variability. The roller bearing guidance minimizes friction, improving efficiency and reducing wear, which lowers maintenance costs over the actuator’s life in high-frequency manufacturing environments.

The QA/8040/61/50 is designed with industry-standard robustness in mind, and many Norgren actuators are provided in configurations that support CE compliance and protective IP-rated housings. For your specific environment, consult the Installation Guide and product datasheets to confirm IP rating and safety certifications relevant to your jurisdiction and application. If a harsher environment is required, discuss protective enclosures or IP-rated variants with your supplier and verify compatibility with the 40 mm bore and 50 mm stroke geometry.

Customer integration is streamlined by the availability of CAD data and an Installation Guide PDF. The CAD download and the installation resource help ensure correct mounting, orientation, and adjacency to other components. For downstream engineering tasks, these resources accelerate model-based design, reduce rework, and support faster commissioning in automated cells and assembly lines.

Expected maintenance benefits include reduced wear thanks to roller bearing guidance, smoother operation, and longer service intervals in high-cycle applications. The predictable performance and easier installation also shorten project timelines and commissioning costs, contributing to a faster return on investment through lower downtime, fewer misalignment issues, and more reliable production throughput.