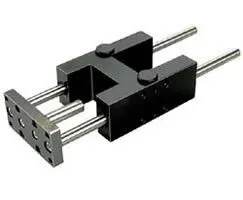

Norgren QA/8050/51/100 Guide Block - 50 mm bore

Part Number: QA/8050/51/100

Quick Summary

Norgren QA/8050/51/100 guide block provides precise linear motion control for automation applications. Engineers often face misalignment, wear, and maintenance-heavy assemblies that slow production cycles and erode uptime. While CE marking and IP-rated options are common considerations in pneumatic systems, always verify certifications and ratings in the official datasheet and installation guides. This block’s compatibility with standard mounting patterns and its robust brand heritage deliver predictable performance, while CAD resources and installation documentation shorten design cycles and facilitate faster onboarding for procurement and engineering teams.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

Feature: 50 mm bore and 100 mm stroke enable a compact yet versatile actuator footprint. Business Impact: Maximizes usable space on crowded automation lines while delivering sufficient travel for common pick-and-place and alignment tasks. Application: Ideal for compact pneumatic actuators in packaging and assembly lines. Feature: Plain bearing guide block design reduces friction and wear over high-cycle operations. Business Impact: Extends service life, lowers maintenance frequency, and stabilizes repeatability. Application: High-speed indexing and fixture positioning in factory automation. Feature: IMI Norgren branding ensures proven reliability and access to global service networks. Business Impact: Reduces downtime risk and simplifies parts replacement through trusted support. Application: General automation and control system integrations. Feature: Availability of CAD models and installation guides accelerates integration. Business Impact: Cuts engineering iteration time, improves first-pass compatibility, and streamlines procurement handoffs. Application: Mechanical design and system integration teams. Feature: Standardized cylinder diameter with compatible mounting patterns improves retrofit and cross-brand interchangeability. Business Impact: Lowers project risk and accelerates modernization programs. Application: Retrofit projects and new machine builds in automation and control systems. Long-tail keywords integrated: pneumatic guide block, 50 mm bore cylinder, 100 mm stroke actuator, IMI Norgren QA series, CAD model download, installation guide PDF, standard mounting pattern, compact linear actuator, automation and control systems.

Get a Quick Quote for a Norgren QA/8050/51/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/51/100?

Enquire Now

FAQs

The QA/8050/51/100 is designed around a 50 mm bore with a 100 mm stroke and a plain bearing guide block, supporting typical Norgren mounting patterns. For installation, refer to the Installation Guide PDF and CAD resources which provide mounting hole layouts, torque specs, and alignment tips to ensure accurate installation and seamless retrofit into existing automation setups.

Core specs include a 50 mm cylinder bore and a 100 mm stroke. The unit uses a plain bearing guide block for smooth, low-friction movement, suitable for high-cycle pneumatic applications. Brand reliability comes from IMI Norgren, with downloadable CAD models to validate fit and integration early in the design phase.

Yes, its 50 mm bore and 100 mm stroke offer a compact yet capable actuator for precise linear motion required in packaging and fixture positioning. For best results, pair with the compatible mounting pattern and verify stroke requirements against your fixture geometry. Use the CAD model to confirm clearances before production.

Certification details like CE marking and IP ratings are common considerations for pneumatic components. Since the provided data does not specify certifications, confirm through the official Datasheet and Installation Guide or contact the supplier to ensure compliance with your regional safety and performance requirements.

The plain bearing design reduces wear, contributing to longer service intervals and lower maintenance costs in high-cycle environments. ROI benefits are realized through improved cycle times, predictable motion, and faster integration via CAD downloads and installation guides, which shorten development and commissioning phases.