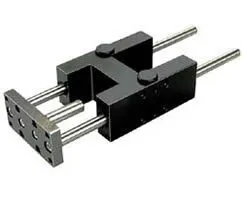

Norgren QA/8050/51/160 Pneumatic Cylinder - 50mm bore

Part Number: QA/8050/51/160

Quick Summary

QA/8050/51/160 Norgren pneumatic cylinder is designed to deliver precise, repeatable linear actuation in automation and packaging applications. In tight automation cells, engineers often face inconsistent stroke, stiction, and maintenance-heavy guidance, which disrupt production and increase downtime. CE compliance and robust IP-rated variants are common in this family to support safe, compliant factory operation. By leveraging a 50 mm bore and a 160 mm stroke, this cylinder supports compact layouts while delivering reliable travel and repeatable positioning. For sourcing and integration, the availability of CAD models and installation guidance helps streamline procurement, engineering validation, and on-site commissioning, delivering measurable business value through faster deployment and reduced maintenance cycles.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The 50 mm bore delivers precise, repeatable piston motion, enabling tight tolerances in automated assembly lines and pick-and-place tasks, reducing part misalignment and rework. This translates to higher first-pass yield and lower cycle times in packaging operations. Feature → Business Impact → Application: The 160 mm stroke provides extended travel with predictable end-of-stroke positioning, improving stroke coverage for long-throw actuations and enabling more efficient control loops in material handling systems. Feature → Business Impact → Application: Plain bearing guide block style reduces friction and wear, delivering smoother operation, quieter cycling, and longer service life in continuous-cycle environments such as bottle packaging and食品 labeling. Feature → Business Impact → Application: Industrial compatibility with standard mounting patterns and Norgren CAD resources reduces installation time and risk, accelerating line upgrades and retrofit projects across automation and control systems. Feature → Business Impact → Application: Rugged construction supports compliance with industry norms and lowers total cost of ownership by minimizing spare parts and maintenance downtime in demanding environments. Feature → Business Impact → Application: Installation advantages, including easy alignment and compatibility with installation guides, enable engineers to validate configurations quickly, limiting commissioning delays and start-up risk.

Get a Quick Quote for a Norgren QA/8050/51/160

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/51/160?

Enquire Now

FAQs

QA/8050/51/160 is designed to align with common Norgren mounting footprints and industry-standard patterns, reducing the need for custom brackets during retrofits. The cylinder supports typical pneumatic control interfaces and compatible connectors, while the provided CAD models help verify fitment before procurement. For best results, confirm bore and stroke against your existing actuators and check the installation guide for torque and alignment guidance.

The model features a 50 mm bore and a 160 mm stroke, enabling compact yet capable linear motion with repeatable positioning. The plain bearing guide block provides low-friction guidance, improving smoothness and reducing stiction over long service intervals. Use the CAD resources to model end-effector clearances, installation tolerances, and mounting forces to optimize cycle time and accuracy.

Yes, the 50 mm bore with a 160 mm stroke offers the balance of compact footprint and travel needed for many pick-and-place tasks in packaging. The plain bearing guidance enhances repeatability under continuous cycling, while standard mounting compatibility simplifies retrofits. For high-speed tasks, validate stroke speed and actuator load with your control system and use the installation guide to ensure proper alignment.

When selecting pneumatic cylinders for regulated environments, look for CE marking and device-level safety certifications where applicable, as well as IP ratings suitable for your washdown or dusty environments. While Norgren’s cylinder family commonly supports these compliance paths, verify the specific unit’s documentation and the installation guide to confirm applicable certifications and operating conditions for your facility.

The plain bearing guidance reduces wear and maintenance frequency, contributing to lower downtime and fewer spare parts over the cylinder’s life. The availability of CAD models and installation guides speeds commissioning, shortening project lead times. Over the asset’s life, the combination of reliable actuation, easy installation, and compatibility with standard control hardware drives a favorable total cost of ownership.