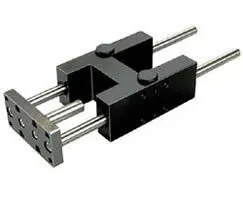

Norgren QA/8050/51/200 Cylinder - 50 mm bore, 200 mm Stroke

Part Number: QA/8050/51/200

Quick Summary

QA/8050/51/200 is a precision guide-block cylinder delivering reliable linear actuation for automation lines. This design addresses common misalignment and wear challenges found in longer-stroke cylinders, helping maintain uptime. Typical industry certifications such as CE marking and IP ratings are key considerations for safety and reliability, while SIL-ready control interfaces can simplify safety integration. The model leverages a compact 50 mm bore and a 200 mm stroke to fit tight automation layouts, with compatibility to standard mounting patterns and CAD resources to accelerate installation and reduce commissioning time.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The 50 mm bore and 200 mm stroke combination delivers smooth, controlled motion with reduced side load, resulting in improved cycle accuracy and longer service life in pick-and-place and material handling tasks. This directly translates to measurable efficiency gains on packaging lines and assembly cells, where repeatability and reliability drive throughput. The guide-block plain bearing style minimizes friction-induced wear, enabling quieter operation and lower maintenance costs across high-cycle environments. Application: automotive, electronics, and consumer-packaged goods lines benefit from predictable actuation and easier alignment during integration. Feature → Business Impact → Application: CAD-ready geometry and downloadable installation guides shorten setup time, lowering total cost of ownership by reducing on-site engineering effort and commissioning delays. Application: retrofit projects and new-line builds in OEM and contract manufacturing settings gain faster time-to-value and consistent performance. Feature → Business Impact → Application: compatibility with standard Norgren mounting patterns and compatible fittings supports scalable automation; engineers can standardize components across multiple lines, decreasing part variety and inventory costs. Feature → Business Impact → Application: robust seals and the 200 mm stroke provide reliable performance in harsher environments, helping meet industry demands for safety, compliance, and long-term reliability. Industry-specific context: in high-speed packaging and automated assembly, predictable actuation reduces product jams and downtime, while ongoing maintenance planning lowers total cost of ownership.

Get a Quick Quote for a Norgren QA/8050/51/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/51/200?

Enquire Now

FAQs

QA/8050/51/200 uses standard Norgren mounting patterns and compatible fittings, enabling straightforward integration into existing automation benches. The included CAD files and the Installation Guide PDF help engineers verify clearance, mounting positions, and alignment prior to assembly, reducing commissioning time and errors.

A 50 mm bore provides balanced force for mid-range actuation tasks, while a 200 mm stroke delivers adequate travel for compact automation cells. The plain bearing guide block minimizes friction and wear, delivering consistent velocity profiles, reduced stiction, and improved repeatability in repetitive cycles.

Yes. The 50 mm bore with 200 mm stroke is well-suited for packaging and pick-and-place workflows where compact footprint and reliable linear actuation are critical. The guide-block design enhances positional stability, helping with precise part placement and reduced product damage over high-cycle runs.

When selecting this cylinder, evaluate CE compliance for European installations and IP-rated sealing for your environment. Consider SIL-safe integration for safety-related functions and ensure the installation adheres to your plant’s safety and maintenance standards. Consult the installation guide and supplier specifications for exact certification details.

Maintenance is typically reduced due to the plain bearing guide system, which minimizes wear and friction. The 200 mm stroke supports long service life in high-cycle tasks, reducing replacement frequency. ROI benefits come from lower downtime, faster installation using CAD resources, and standardized compatibility across lines, delivering faster time-to-value and lower total cost of ownership.