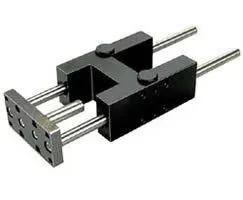

Norgren QA/8050/51/250 Guide Block - 50 mm Bore

Part Number: QA/8050/51/250

Quick Summary

QA/8050/51/250 guide block delivers precise linear guidance for pneumatic automation. Engineers rely on consistent stroke accuracy in tight spaces, where misalignment and bearing wear threaten uptime. When specifying components, verify CE conformity, IP ratings for rugged environments, and SIL relevance to safety functions. By matching standard bore sizes and stroke lengths, this guide block integrates with existing Norgren systems, shortening installation time and lowering total cost of ownership. This combination supports reliable automation performance while enabling seamless scalability for future line upgrades.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

Feature: 50 mm bore with 250 mm stroke provides substantial travel in a compact footprint. Business Impact: Enables flexible machine layouts and reduces the number of intermediate parts needed, cutting assembly time and spare parts cost. Application: Suitable for compact automation cells and robotic guidance where precise, repeatable motion is required. Feature: Plain bearing style guide block offers low friction and predictable wear. Business Impact: Improves service life and lowers maintenance intervals, delivering higher mean time between failures (MTBF). Application: Long-life guidance in harsh environments typical of packaging and material handling lines. Feature: Interchangeability with standard mounting patterns and Norgren-compatible accessories. Business Impact: Simplifies retrofits and reduces commissioning risk, accelerating time-to-market for upgrades. Application: Retrofit projects or new lines needing quick integration with existing control architectures. Feature: Robust construction and compatibility with installation guides and CAD resources. Business Impact: Faster installation, fewer errors, and easier compliance verification. Application: Engineering workflows that rely on accurate CAD data and authoritative installation procedures. Feature: 50 mm bore / 250 mm stroke dimensions with plain bearing guidance. Business Impact: Aligns with common pneumatic system standards, minimizing customization needs. Application: General automation and control systems across multiple industries including packaging, handling, and machine tools.

Get a Quick Quote for a Norgren QA/8050/51/250

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/51/250?

Enquire Now

FAQs

To install, align the guide block with the mounting pattern on the actuator, secure with the recommended screws, and verify parallelism to the sliding surface. Use the provided installation guide to ensure correct bolt torque and initial travel clearance. If retrofitting, confirm compatibility with existing brackets and alignment shims to avoid binding and uneven wear.

Key specifications include a 50 mm bore and 250 mm stroke, with a plain bearing guide block design. The assembly is designed for linear guidance in pneumatic automation, compatible with standard mounting patterns and Norgren accessories. These dimensions support medium-range travel in compact automation cells while maintaining reliable alignment.

Yes, the 50 mm bore and 250 mm stroke fit typical packaging line needs, delivering repeatable positioning and smooth motion. Its plain bearing design minimizes friction and maintenance, helping to sustain throughput. Ensure the load profile and cycle rate match the guide block’s travel and wear characteristics for optimal performance.

buyers should verify CE conformity for European markets, and review IP protection levels for ingress protection in harsh environments. If safety-critical applications are involved, check SIL relevance in your system’s risk assessment and ensure the component’s documentation supports requisite certifications from the manufacturer.

Expect reduced downtime thanks to low-friction plain bearings and predictable wear, which extend service intervals and MTBF. The compatibility with standard mounting patterns minimizes retrofit risk and installation costs, delivering a faster return on investment through improved uptime and easier integration with existing automation architectures.