Norgren QA/8050/51/320 Pneumatic Cylinder - 320 mm Stroke

Part Number: QA/8050/51/320

Quick Summary

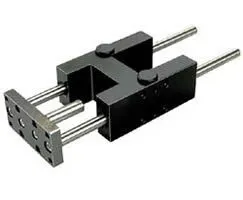

Norgren QA/8050/51/320 is a precision pneumatic cylinder designed for high-precision linear actuation in automation lines. It addresses common pain points such as misalignment, wear, and downtime that disrupt cycle times and jeopardize part quality. In industry practice, CE compliance, IP protection levels, and SIL safety considerations guide selection and installation decisions, ensuring operator safety and system reliability. The robust 50 mm bore and 320 mm stroke translate to repeatable performance in confined spaces, enabling tighter tolerances and longer service life. By providing CAD files and installation guides, we help design teams accelerate sourcing, reduce integration risk, and standardize components across multiple lines. This translates to lower total cost of ownership through easier maintenance and consistent performance.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

Feature: Guide block plain bearing style 51 with a 50 mm bore and 320 mm stroke provides smooth, load-balanced actuation. Business Impact: reduces internal friction and wear, delivering improved repeatability and longer service life. Application: ideal for precise positioning and alignment in packaging and assembly cells. Feature: Sealed, robust construction designed for reliable operation in compact footprints. Business Impact: enables reliable performance in tight automation spaces, supporting higher line efficiencies and reduced maintenance intervals. Application: suitable for vertical or horizontal mounting in compact automation stacks. Feature: Availability of CAD models and Installation Guide (PDF). Business Impact: speeds commissioning, minimizes setup errors, and shortens time-to-first-run. Application: system integrators and OEMs deploying line-side components in food & beverage, packaging, and automotive applications. Feature: Proven bore/ stroke combination (50 mm bore, 320 mm stroke) for balanced force with compact size. Business Impact: consistent actuation under varying loads, improving cycle accuracy and reducing rework. Application: push/pull tasks in constrained automation zones where precise travel is critical. Feature: Global support ecosystem and part availability from Norgren. Business Impact: minimizes downtime through rapid spare parts access and engineering assistance. Application: modern production lines requiring dependable uptime and quick maintenance turnaround.

Get a Quick Quote for a Norgren QA/8050/51/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/51/320?

Enquire Now

FAQs

The QA/8050/51/320 uses Norgren’s guide block plain bearing style and is designed for straightforward integration with common mounting arrangements in automation cells. Refer to the CAD download and Installation Guide for exact mounting dimensions and adaptor options to ensure a secure fit on your chassis.

Key specs include a 50 mm bore and a 320 mm stroke, branded as IMI Norgren. The cylinder provides precise linear actuation suitable for repeatable positioning tasks and compact installation footprints in automation lines.

Yes. The 50 mm bore and 320 mm stroke combination supports reliable push/pull movements in compact spaces, delivering consistent actuation for pick-and-place and alignment in packaging lines, with CAD resources to simplify integration.

Industry-standard expectations for automation components often include CE compliance and suitable IP ratings. While the data here references general industry practices, always verify the specific model documentation or contact Norgren support to confirm current CE and IP ratings for your application.

Expect reduced downtime due to robust guide block bearing design and longer service life under load. Availability of CAD models and installation guides accelerates commissioning, lowering design risk and enabling faster return on investment through improved uptime and consistent performance.