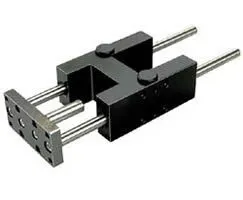

Norgren QA/8050/51/400 Guide block - 50 mm bore

Part Number: QA/8050/51/400

Quick Summary

Norgren guide block QA/8050/51/400 provides precise linear motion for automation and packaging. Users struggle with misalignment and wear in long-stroke cylinders, but this plain bearing design minimizes play and extends service life. Certifications to verify include CE compliance, IP ratings, and SIL safety considerations for critical automation. By delivering reliable actuation with straightforward installation and CAD-ready resources, it supports efficient line automation, reduced downtime, and lower lifecycle costs.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

50 mm bore delivers a compact yet robust actuator with predictable force delivery. This results in a smaller footprint on crowded automation cells and easier integration with other Norgren components, enabling smoother layout planning and faster line changes in packaging and assembly applications. 400 mm stroke provides extended travel without additional modules, reducing the need for multiple actuators and simplifying machine design for indexing and material handling. The plain bearing guide block minimizes friction and wear, translating to longer service intervals and lower maintenance costs on high-cycle production lines. Compatibility with IMI Norgren components and CAD download availability speeds up engineering and reduces part-number errors during design, installation, and commissioning. Easy mounting and alignment, supported by clear installation guides, address common objections about retrofits and nonstandard frames. This combination delivers a reliable, cost-efficient actuation solution for automation cells that demand repeatable motion and predictable performance. In practice, engineers favor this configuration for compact robotics, pick-and-place stations, and conveyor-based systems, where space, uptime, and traceable maintenance matter most.

Get a Quick Quote for a Norgren QA/8050/51/400

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/51/400?

Enquire Now

FAQs

QA/8050/51/400 uses a compact guide block design with standardized mounting interfaces common to IMI Norgren assemblies. For installation, verify alignment with adjacent guide rails and mounting plates, then utilize compatible fasteners and connector patterns from Norgren catalogs. The CAD files and installation guide provide recommended torque values, mounting spacing, and alignment tips to minimize runout and enhance repeatability in automation cells.

The unit features a 50 mm bore and a 400 mm stroke. This combination yields a compact actuator suited for tight spaces while delivering respectable travel and force characteristics. When selecting this model, ensure stroke compatibility with your available envelope and consider end-of-stroke cushioning and mounting posture to maintain repeatable positioning in long-cycle applications.

Yes, the QA/8050/51/400 is well-suited for pick-and-place in packaging lines where space is at a premium and reliable repeatable motion is essential. The plain bearing guide reduces friction wear over many cycles, and the 400 mm stroke supports longer reach without additional modules. For best results, pair with compatible end-of-stroke cushions and proper mounting to minimize installation-induced misalignment.

Certification details for this specific model are not listed in the provided data. In practice, similar Norgren guide blocks are evaluated for CE compliance and appropriate IP protection levels, with SIL safety considerations addressed during system design. Always confirm the exact certifications with the supplier and reference the latest manufacturer documentation during procurement and validation activities.

Norgren provides CAD resources and an Installation Guide (PDF) to streamline engineering and commissioning. Access CAD models via the provided CAD download link and consult the Installation Guide for step-by-step mounting, alignment, and maintenance procedures. These resources help reduce downtime, improve first-pass assembly accuracy, and support ongoing reliability of automation systems using this guide block.