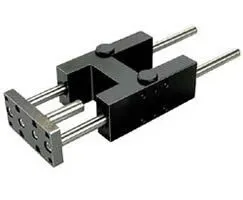

Norgren QA/8050/51/50 Guide Block - 50 mm Stroke

Part Number: QA/8050/51/50

Quick Summary

QA/8050/51/50 guide block delivers precise linear motion for compact automation in manufacturing lines, enabling tighter tolerances and repeatable results. Operators often wrestle with misalignment, wear, and downtime when selecting generic cylinders that fail to match the required stroke or bore. In industrial environments, CE conformity, robust IP-rated design, and SIL considerations are common safety and reliability requirements. This solution addresses these needs with predictable travel, a compact footprint, and easy integration with standard mounting patterns. By leveraging CAD resources and a trusted brand, it also reduces engineering time and total cost of ownership while improving throughput on inline packaging and assembly lines.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

Feature: 50 mm bore and 50 mm stroke provide robust linear motion in a compact footprint. Business Impact: preserves reach and stroke length while enabling tighter machine layouts and higher-density tooling. Application: ideal for inline packaging, automated assembly, and material-handling cells where space is at a premium. Feature: Plain bearing guide block reduces friction and wear compared with heavily engineered guidance, extending service life and lowering replacement intervals. Business Impact: lower maintenance costs and fewer unscheduled downtime events in high-cycle applications. Application: commonly installed on compact cylinders in pick-and-place and robotics-friendly automation lines. Feature: Norgren brand quality and CAD-download availability streamline engineering workflows. Business Impact: faster design iterations, fewer integration errors, and quicker time-to-production. Application: compatible with standard mounting patterns and end-stop configurations used in DIN/ISO frames across automation projects. Feature: Standard mounting compatibility and clear installation references simplify commissioning. Business Impact: reduces installation time by hours per line and minimizes field adjustments. Application: retrofits and new builds alike, where engineers value predictable mounting and plug-and-play cabling or plumbing. Feature: Documentation and downloadable CAD data improve setup accuracy and spare-part planning. Business Impact: smoother maintenance scheduling, accurate BOMs, and improved vendor consolidation. Application: procurement teams benefit from consistent, reusable models across multiple projects, cutting engineering overhead. Objection handling: perceived cost can be offset by extended lifecycle—this plain bearing guide block delivers longer cycling life under typical pneumatic duty cycles and supports lean manufacturing goals. Counterpoint: the up-front investment pays back through reduced downtime, faster changeovers, and better repeatability on high-uptime lines.

Get a Quick Quote for a Norgren QA/8050/51/50

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/51/50?

Enquire Now

FAQs

QA/8050/51/50 uses common ISO/DIN mounting conventions found on pneumatic cylinders, matching 50 mm bore products, end cap configurations, and side ports. This compatibility means you can reuse existing mounting plates, brackets, and hoses without needing custom adapters. For best results, reference the CAD model and installation guide before integration to avoid misalignment.

Key performance specs include a 50 mm bore and a 50 mm stroke, plain bearing guidance for smooth travel, and a compact form factor designed for high-density layouts. It supports repeatable actuations within standard factory air pressure ranges. In practice, engineers report predictable piston speed and reduced travel variation, translating to tighter process windows and fewer defects.

Yes. The 50 mm bore and 50 mm stroke fit tight spaces typical of packaging and assembly lines. The plain bearing guide reduces friction for sustained cycling, while standard mounting patterns simplify line upgrades. In high-throughput cells, the block supports consistent travel and quick setup, minimizing line stoppages during changeovers.

For industrial use, verify CE conformity and applicable IP ratings, and consider SIL requirements for safety-critical lines. While the QA/8050/51/50 data focuses on mechanical dimensions, most Norgren guides provide documentation aligning with European and international standards. Always check the product datasheet and CAD downloads for the latest certification and compliance statements.

Compared with generic blocks, this guide block typically reduces downtime through longer service life and smoother operation. The 50 mm bore/ stroke and plain bearing design minimize wear, while CAD availability accelerates commissioning. Over multiple lines, maintenance scheduling improves, spare parts consumption decreases, and overall uptime increases, delivering a favorable return on investment during lean manufacturing initiatives.