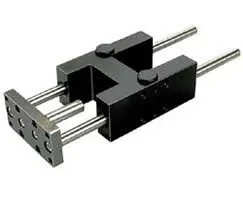

Norgren QA/8050/51/500 Guide Block - 50 mm Bore, 500 mm Stroke

Part Number: QA/8050/51/500

Quick Summary

QA/8050/51/500 guide block provides precise linear guidance for automated machinery. In tight automation cells, misalignment and wear can derail cycles; this block helps mitigate that. Certifications to consider include CE compliance for European use, IP ratings for protective environments, and SIL-related safety documentation for critical applications. By focusing on a 50 mm bore and a 500 mm stroke, it integrates smoothly with Norgren actuators and CAD resources, simplifying installation and replacement. The result is extended service life, predictable motion, and lower maintenance costs, making it a solid choice for design engineers and procurement teams aiming to improve uptime and total cost of ownership.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

The QA/8050/51/500 guide block features a 50 mm bore and 500 mm stroke that deliver stable, repeatable motion under typical automation loads. This translates to reduced positional drift and tighter tolerances across packaging, assembly, and pick-and-place cells. Engineers can rely on consistent guiding performance in compact spaces, enabling faster cycle times and easier mounting to standard Norgren actuators. Printed with a plain bearing style, the block minimizes maintenance needs while delivering robust wear resistance in cleanroom-to-industrial environments. The low-friction design lowers energy consumption and extends service intervals, which reduces downtime in high-cycle applications like sorting lines or conveyor-guided systems. The QA/8050/51/500 is designed for seamless compatibility with IMI Norgren components and readily available CAD models and installation guides. Quick mounting and standardized mounting holes accelerate integration, reduce design risk, and shorten project lead times for machine builders and integrators. Some teams worry about wear in plain bearing blocks at high speeds; the answer is optimized lubrication intervals and correct selection based on stroke and cycle frequency. The 50 mm bore and precise fit support stable motion while offering cost-effective long-term operation, especially when paired with properly sized seals and lubrication. Industry experience shows that using certified guidance blocks from reputable brands can improve uptime and reduce maintenance costs over the product life.

Get a Quick Quote for a Norgren QA/8050/51/500

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/51/500?

Enquire Now

FAQs

Begin by confirming mounting pattern compatibility with your cylinder flange. Align the guide block to the actuator shaft, insert through-bolts with appropriate spacers, and torque to the recommended specification. Use the provided CAD model to verify fitment and consult the Installation Guide PDF for lubrication intervals and sealing recommendations.

Key specs include a 50 mm bore and a 500 mm stroke, with a plain bearing style for low friction. This configuration delivers stable, repeatable motion and easy integration with IMI Norgren actuators, suitable for compact automation cells and packaging lines.

Yes, its plain bearing design minimizes maintenance in high-cycle environments, but lubrication schedule and stroke frequency should be matched to load to avoid premature wear. Consider using the CAD resources and Installation Guide to optimize mounting and lubrication for your cycle rates.

This data sheet does not list specific certifications. When deploying in Europe, verify CE compliance and consult Norgren for IP ratings and SIL safety documentation as required by your application and plant standards.

The part's robust plain bearing design and easy installation reduce downtime and maintenance costs over the life of an automation line. Quick integration with CAD downloads and installation guides helps shorten project cycles and stabilize uptime in manufacturing environments.