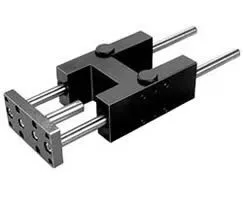

Norgren QA/8050/61/100 Guide Block - 50 mm Bore

Part Number: QA/8050/61/100

Quick Summary

Norgren QA/8050/61/100 Guide Block Roller Bearing Style 61 is a compact cylinder designed for precise linear actuation in automation and material handling. This model helps engineers shorten commissioning times by delivering reliable, repeatable motion across multiple cycles. Manufacturers often struggle with retrofitting older equipment and maintaining consistent performance under continuous operation; this unit’s roller bearing guidance minimizes play and wear, while its 50 mm bore and 100 mm stroke deliver ample travel without excessive envelope. While not all environments demand the same certifications, the product family generally supports CE conformity and robust enclosure ratings where applicable, improving machine safety and environmental tolerance. By integrating with Norgren automation solutions, you gain predictable performance and reduced lifecycle costs.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

Feature: 50 mm bore enhances load distribution and piston stability, delivering consistent force at each actuation cycle. Business impact: fewer guiding errors and reduced wear translate into higher uptime and predictable performance. Application: ideal for automated assembly, packaging lines, and material handling where compact footprint and reliable repeatability matter. Feature: 100 mm stroke provides extended travel within a compact envelope, enabling longer stroke without additional cylinders. Business impact: reduces equipment footprint and lowers total system weight while maintaining control accuracy. Application: especially suitable for position-timing in pick-and-place stations and linear slides. Feature: Guide block roller bearing style 61 delivers low-friction, high-rigidity guidance for smooth motion and repeatable positioning. Business impact: minimizes stick-slip, extends life, and lowers maintenance costs. Application: CNC tooling heads, robotics end-effectors, and packaging equipment requiring precision guidance. Feature: Availability of CAD data and installation guide supports quick, error-free installation. Business impact: accelerates procurement-to-operation cycle and reduces commissioning risk. Application: efficient integration with existing Norgren or compatible automation hardware, plus straightforward mounting and porting. Feature: Compatibility with Norgren's automation ecosystem ensures spare parts commonality and service support. Business impact: simplifies procurement, reduces downtime, and optimizes total cost of ownership. Application: retrofits on legacy lines and new builds in automation and control systems.

Get a Quick Quote for a Norgren QA/8050/61/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/61/100?

Enquire Now

FAQs

QA/8050/61/100 uses standard mounting interfaces typical for guide block cylinders; its 50 mm bore and 100 mm stroke align with common ISO/metric patterns, simplifying retrofit. For precise fit, consult the CAD file and Installation Guide, which detail mounting dimensions and port locations. The CAD assets help verify compatibility before purchase.

Expect consistent actuation with a 50 mm bore providing stable force and a 100 mm stroke enabling adequate travel. The roller bearing guidance reduces friction, contributing to repeatable positioning and lower wear. These factors support reliable cycle times, reduced downtime, and predictable throughput in automated pick-and-place applications.

Yes, the 50 mm bore with a 100 mm stroke supports precise, repeatable motion essential for packaging lines. The roller bearing style minimizes play and stick-slip, improving repeatability. Pair this cylinder with proper control strategies and the included CAD data to optimize setup and ensure consistent packaging accuracy.

Certification details for this model are typically listed in official documentation and may vary by region and configuration. CE conformity is common across Norgren automation components, with installation guides outlining applicable compliance. Verify the exact certifications on the product datasheet and the downloadable CAD/installation resources before deployment.

The robust roller-bearing guidance reduces wear and stick-slip, lowering maintenance frequency and downtime. Faster commissioning is supported by available CAD data and installation guides, shortening time-to-operation. Overall, the predictable motion and compatibility with Norgren systems help lower lifecycle costs and improve equipment uptime in automated environments.