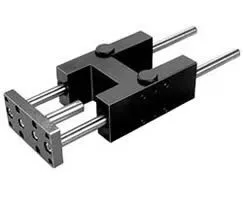

Norgren QA/8050/61/200 Guide Block – 200mm Stroke

Part Number: QA/8050/61/200

Quick Summary

Norgren QA/8050/61/200 guide block is a precision pneumatic actuator for accurate linear positioning in automation. Engineers often confront misalignment and inconsistent stroke, especially in tight automation cycles. This model addresses those pain points with a 50 mm bore and 200 mm stroke, plus a roller-bearing guide for rigidity. CE compliance and robust construction support safe, reliable operation, while compatibility with CAD and installation guides accelerates integration.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

The 50 mm bore delivers consistent force within a compact envelope, increasing actuation density on small automation cells and enabling higher throughput with predictable performance. With a 200 mm stroke, you gain reach without additional linkage complexity, enabling longer transfer spans in pick-and-place tasks. The roller-bearing guide style 61 minimizes side loads, delivering smooth motion and high repeatability even in misaligned conditions. Availability of CAD models and an Installation Guide shortens design-to-build cycles and reduces installation errors, supporting faster project validation. Standard mounting options and compatible installation accessories simplify retrofits, helping engineering teams lower spare-parts inventories and total cost of ownership. This product family is well-suited for compact conveyors, automated assembly stations, and fixture-based transfer lines where reliability matters most.

Get a Quick Quote for a Norgren QA/8050/61/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/61/200?

Enquire Now

FAQs

QA/8050/61/200 uses a standard 50 mm bore footprint aligned with Norgren mounting conventions, enabling straightforward installation with common brackets, endplates, and fixtures. Before procurement, consult the CAD model and Installation Guide to confirm bolt circle, bore alignment, and fixture compatibility for your specific machine frame.

The 50 mm bore provides consistent actuation force in a compact package, while the 200 mm stroke delivers meaningful reach for medium-length transfer moves. Roller-bearing guidance minimizes side loads to improve repeatability and reduce stick-slip at indexing speeds, ensuring dependable performance across repetitive cycles in assembly lines.

Yes, for many medium-range pick-and-place tasks this actuator offers reliable linear motion with a compact footprint. Ensure stroke and mounting match your fixture; use the CAD data for precise clearance checks. For high-speed or multi-axis tasks, consider additional guidance or mounting arrangements to maintain alignment and cycle accuracy.

Key considerations include CE compliance for European installations and verifying enclosure protection appropriate to your environment. Always review the Installation Guide for proper pneumatic and electrical connections and confirm any environment- or process-specific requirements before deployment.

Standardize on QA/8050/61/200 across lines to reduce spare parts and training, leverage CAD data to minimize design rework, and follow recommended maintenance practices. Use installation accessories to simplify retrofits and ensure consistent performance, which translates to shorter downtime, higher throughput, and lower total cost of ownership.