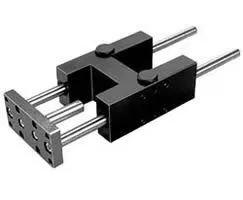

Norgren QA/8050/61/250 Pneumatic Cylinder - 50 mm Bore

Part Number: QA/8050/61/250

Quick Summary

QA/8050/61/250 pneumatic cylinder delivers precise linear actuation for automated assembly and packaging lines. Engineers often contend with misalignment, stroke wear, and downtime, which can erode productivity and increase maintenance costs. In regulated environments, CE marking, IP ratings, and SIL safety considerations are important. Designed to integrate with standard automation systems, this actuator supports scalable production while helping reduce cycle times and changeover complexity. The combination of a compact 50 mm bore with a 250 mm stroke delivers reliable motion in tight spaces, and its robust roller-bearing guide helps extend service life, translating to lower total cost of ownership over multiple production shifts.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

Feature: 50 mm bore and 250 mm stroke deliver a compact yet long-travel actuator. Business Impact: Enables efficient use of small footprints on crowded lines while maintaining reach and force capacity. Application: Ideal for automated assembly fixtures and packaging stations where space is at a premium and precise travel is required. Feature: Guide block roller bearing style 61 minimizes side loads and tilting. Business Impact: Reduces wear, lowers maintenance frequency, and improves positional repeatability. Application: Suitable for high-cycle operations and applications demanding sustained accuracy across long production runs. Feature: IMI Norgren heritage and compatibility with common automation components. Business Impact: Accelerates design-in and minimizes integration risk, reducing engineering time and vendor fatigue. Application: Retrofit projects and new lines benefit from familiar mounting patterns and readily available spare parts. Feature: Comprehensive documentation and CAD resources available for quick deployment. Business Impact: Shortens design cycles, speeds validation, and enhances prototyping accuracy. Application: Engineers can import models into MEP and PLC layouts to verify clearance and interfacing before fabrication. Feature: Installation and maintenance friendliness with standard mounting interfaces. Business Impact: Simplifies installation, lowers commissioning time, and supports predictable maintenance planning. Application: Service teams can execute routine checks with minimal tools, maximizing uptime and reliability.

Get a Quick Quote for a Norgren QA/8050/61/250

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/61/250?

Enquire Now

FAQs

This model uses conventional 50 mm bore mounting interfaces common to industrial pneumatic cylinders. For rapid design-in, refer to the included CAD downloads and the Installation Guide (PDF) to verify end-cap options, mounting spacers, and alignment procedures. Ensuring correct alignment reduces startup friction and extends service life in high-cycle lines.

The actuator features a 50 mm bore and 250 mm stroke, delivering consistent travel and load handling within a compact footprint. Roller-bearing guides minimize lateral movement under dynamic loads, improving repeatability at higher cycle rates. These attributes support faster throughput in automated assembly and packaging applications.

For challenging environments, the choice of seals and potential protective enclosures matters. While the unit’s roller-bearing guide reduces wear, ensure proper sealing and enclosure to meet your IP requirements and washdown practices. Consult the Installation Guide and consider enclosure ratings and lubricants compatible with your process.

In regulated industries, CE marking and appropriate IP ratings are common considerations, along with SIL safety integration where required by the process. Verify regional requirements with your supplier and reference the installation documentation to confirm compatibility with safety systems and risk assessments.

The roller-bearing guide reduces wear and friction, contributing to longer service intervals and lower downtime. With CAD resources and clear mounting guidelines, engineering time is minimized and commissioning is quicker. A predictable maintenance schedule coupled with available spare parts supports steady production and improved total cost of ownership.