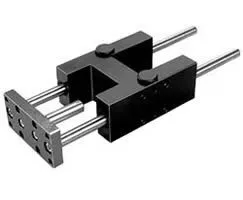

Norgren QA/8050/61/320 Guide block roller - 320mm stroke

Part Number: QA/8050/61/320

Quick Summary

Norgren QA/8050/61/320 is a guide block roller actuator designed for precise linear motion in automation systems. Engineers often contend with misalignment, stiction, and downtime when using standard cylinders on fast, repetitive cycles. This unit is CE-compliant and engineered for compatibility with typical IP-rated environments and SIL-ready safety considerations, ensuring safer integration in complex lines. With a 50 mm bore and a 320 mm stroke, it delivers consistent force and extended travel in compact spaces. The rugged roller-bearing guidance minimizes friction, enhances repeatability, and reduces wear, while CAD downloads and installation guides speed design and commissioning. In short, it lowers maintenance costs and boosts uptime for packaging, assembly, and material-handling applications.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

With a 50 mm bore and a 320 mm stroke, QA/8050/61/320 delivers substantial stroke length in a compact cylinder, making it well suited for packaging lines and automated assembly cells. This combination enables longer travel between end stops without expanding the overall footprint, supporting higher throughput on crowded production floors. In practice, the extra stroke reduces the need for additional actuators and transfer mechanisms, lowering capital expenditure and minimizing line complexity. The guide block roller bearing design reduces friction and stiction, delivering smoother motion, tighter run-out, and improved repeatability across thousands of cycles. That translates to lower cycle time variability, less product-to-product inconsistency, and reduced premature wear on rods and seals. In high-cycle environments, these mechanical advantages extend service intervals and drive down maintenance costs over the life of the line. Design and commissioning are accelerated by available CAD downloads and the Installation Guide, helping engineers slot the unit into existing lines with minimal redesign. Compatibility with standard pneumatic controls, fittings, and mounting accessories simplifies retrofits and reduces risk during upgrades. The actuator's mounting footprint and long-stroke capability also unlock new layout possibilities, enabling more flexible cell design. CE compliance and safety-focused construction support compliant automation deployments in regulated environments, while the robust housing is designed to tolerate typical factory conditions. The quiet operation and controlled acceleration profile minimize vibration and shock transfer to delicate workpieces. The transparent maintenance path—common seal replacements and readily available spare parts—reduces downtime and inventory costs. Across manufacturing segments such as packaging, material handling, and automotive assembly, customers report improved uptime and predictable performance from QA/8050/61/320 compared with older cylinders. The combination of reliability, ease of integration, and supporting documentation delivers clear ROI through reduced downtime, lean design cycles, and lower total cost of ownership.

Get a Quick Quote for a Norgren QA/8050/61/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/61/320?

Enquire Now

FAQs

Begin by confirming the mounting footprint matches common ISO patterns used on Norgren guide cylinders. QA/8050/61/320 supports standard clevis and flange fixtures; ensure a 50 mm bore and 320 mm stroke fit your stroke envelope. Use the provided CAD files and the Installation Guide to plan routing, attach with compatible fasteners, and perform alignment checks to prevent binding.

Key specs include a 50 mm bore and 320 mm stroke for extended travel in tight spaces, a roller bearing guide for smooth motion, and robust end-of-stroke performance. The design minimizes friction, enhances repeatability, and supports high-cycle operation in automation lines. Refer to the datasheet for operating pressure ranges and temperature limits relevant to your application.

Yes. The long stroke and precise motion suit packaging, pick-and-place, and material handling lines. The compact footprint fits tight stations, while the roller-bearing guidance reduces vibration and helps maintain product alignment during fast cycles, improving throughput and reducing misfeed instances.

The QA/8050/61/320 is CE-compliant and designed with safety considerations appropriate for automation environments. While SIL and IP ratings may vary by configuration, the design supports safe operation within standard industrial control systems and can be integrated with safety devices as part of a compliant automation deployment.

Maintenance is straightforward thanks to modular seals and widely available spare parts. The roller-bearing guide reduces wear and extends service intervals, boosting uptime. CAD and installation documentation shorten design cycles, delivering faster time-to-value and a favorable total cost of ownership in high-volume production settings.