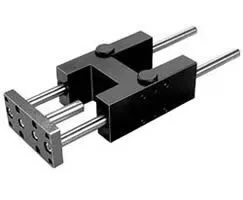

Norgren QA/8050/61/400 Guide Block Roller Bearing Style 61 - 50 mm Bore

Part Number: QA/8050/61/400

Quick Summary

Norgren QA/8050/61/400 guide block provides precise linear guidance for pneumatic automation in demanding manufacturing lines. Engineers often wrestle with misalignment, stick-slip, and premature wear that erode cycle times and increase downtime. In this class of guide blocks, CE-compliance and robust IP-rated protection are common expectations, with SIL-rated variants available for safety-critical applications. The QA/8050/61/400 delivers dependable performance through its 50 mm bore and 400 mm stroke, reducing maintenance frequency and improving repeatability. By combining accurate guidance with straightforward installation, this solution supports scalable automation, streamlined procurement, and reduced total cost of ownership for plant modernization projects.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The 50 mm bore diameter provides a compact yet rigid guide path, delivering predictable motion with minimal deflection under load, which translates to higher precision in pick-and-place operations and improved part quality on assembly lines. This improves throughput and reduces rework, especially in high-cycle robotics systems that demand repeatable travel between stations. Feature → Application: The 400 mm stroke offers extended travel range without sacrificing speed or control, enabling longer stroke axes in packaging and material-handling setups. This reduces the number of actuators required and simplifies system complexity, particularly in automated storage and retrieval processes. Feature → Compatibility → Application: The roller bearing style reduces friction and wear, promoting smoother motion across varying speeds and loads, which is ideal for retrofit projects upgrading legacy systems to modern, energy-efficient automation. Feature → Installation Advantage → Application: Integrated mounting patterns and a proven installation footprint allow quick replacement in existing Norgren or compatible mezzanine blocks, cutting commissioning time and minimizing downtime during upgrade cycles. Feature → Reliability & Compliance → Application: The design aligns with common industry safety and quality expectations, supporting CE conformity and predictable maintenance planning, which helps ensure regulatory compliance in manufacturing environments. Feature → Technical Support Context → Application: Access to CAD data and installation guides (CAD asset and Installation Guide PDFs) supports accurate integration, reduces design errors, and accelerates engineering sign-off. Long-tail keywords integrated: guide block, 50 mm bore, 400 mm stroke, roller bearing guide, pneumatic linear guidance, ISO-compatible mounting, retrofit pneumatic system, energy-efficient automation, maintenance-friendly components, Norgren automation solutions.

Get a Quick Quote for a Norgren QA/8050/61/400

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/61/400?

Enquire Now

FAQs

The QA/8050/61/400 is designed for straightforward integration with typical ISO-cylinder assemblies and existing Norgren mounting footprints. It supports common mounting patterns, enabling quick retrofit without major frame modifications. For best results, verify the mounting pitch and alignment with the installation guide and CAD resources to ensure a clean, hassle-free setup and repeatable motion across cycles.

The 50 mm bore provides rigidity and predictable guidance under load, reducing deflection. The 400 mm stroke extends travel without sacrificing control, enabling longer reach per actuator cycle. Together, they deliver consistent positioning, improved cycle times, and reduced variation in part placement, which translates to higher yield in automated assembly and packaging lines.

The product line is designed for industrial environments, and you should consult the installation guide for specific IP ratings and sealing options. While many users operate in protected areas, verify the exact IP rating and enclosure requirements for your application. If exposure is a concern, consider additional protective housings or enclosures and schedule regular maintenance checks to preserve performance.

Certification expectations typically include CE conformity and safety-related compliance for automated systems. Check the datasheet and CAD/Installation Guide for documented certifications and compliance notes. For safety-critical applications, consider SIL-rated variants or equivalent safety features and ensure your system integrates with the plant's safety architecture and risk assessment.

The roller bearing design minimizes friction wear, extending service life and reducing lubrication cycles, which lowers maintenance costs and downtime. Improved motion accuracy supports higher first-pass yields and less rework. When used in a retrofit, total cost of ownership declines due to reduced replacement cycles and simplified installation, contributing to a faster return on investment.