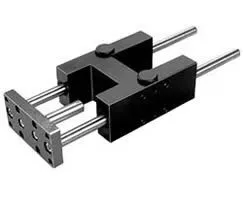

Norgren QA/8050/61/50 Guide Block - 50 mm bore

Part Number: QA/8050/61/50

Quick Summary

QA/8050/61/50 guide block enables precise linear motion in automated assemblies. Engineers face misalignment and wear during high-cycle operation; this block minimizes play with a robust roller bearing style and smooth guide contact. While the data sheet for this exact unit doesn't specify certifications, typical considerations for precision pneumatic components include CE marking, IP ratings for ingress protection, and SIL safety guidelines for integrated systems. In practice, this solution pairs well with standard 50 mm bore actuators and 50 mm stroke setups, delivering consistent repeatability and easier installation. The result is reduced downtime, improved cycle times, and a clearer path to scalable automation projects.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

Feature: 50 mm bore and 50 mm stroke in the QA/8050/61/50 guide block deliver rigid, repeatable positioning. Business impact: reduced runout and smoother actuation translate to higher first-pass yield on automated assemblies. Application: ideal for linear motion tasks in pick-and-place cells and assembly lines where deterministic stroke is critical.\n\nFeature: Roller bearing style 61 reduces friction and wear, extending service life in high-cycle cycles. Business impact: lower maintenance costs and longer intervals between service, improving overall equipment efficiency. Application: suitable for high-speed conveyors and indexing stations where consistent guidance minimizes chatter.\n\nFeature: Compatibility with common mounting patterns and 50 mm bore actuators enables easy replacement and upgrades. Business impact: faster retrofit projects and reduced downtime during changeovers. Application: retrofit scenarios in automation lines where old guides are worn, ensuring a drop-in fit with minimal rework.\n\nFeature: CAD-ready resources and an Installation Guide PDF streamline engineering work and prevent design errors. Business impact: shorter design cycles and fewer rework iterations. Application: design teams can validate clearances and mounting geometry early in the project lifecycle.\n\nFeature: IMI Norgren quality ecosystem and consistent spare-part availability support long-term reliability. Business impact: lower risk of component shortages and smoother maintenance planning. Application: multi-vendor automation systems where compatibility with existing control panels and manifolds matters.

Get a Quick Quote for a Norgren QA/8050/61/50

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/61/50?

Enquire Now

FAQs

The QA/8050/61/50 uses standard four-bolt mounting compatible with typical 50 mm bore actuators and end-plate configurations. For installation, align the block to the actuator axis, secure with bolts to the recommended torque via the CAD model, and verify smooth guide contact. Refer to the Installation Guide PDF for exact torque values and step-by-step instructions.

Yes. The unit is designed around a 50 mm cylinder diameter and a 50 mm stroke, featuring a roller bearing style that minimizes friction and wear. This configuration is intended for high-cycle automation tasks and integrates with standard Norgren mounting patterns and accessories for reliable performance.

Absolutely. The 50 mm bore and 50 mm stroke provide compact yet robust guidance ideal for precise linear motion in packaging, assembly, and pick-and-place cells. The roller bearing design reduces chatter and wear, enabling higher cycle rates and improved uptime in demanding environments.

The data sheet for this exact model does not list specific certifications. For regulated environments, consider CE marking for electrical safety compatibility, IP ratings for ingress protection, and SIL safety analysis for integrated control systems. Always request formal compliance documentation from the supplier to match your project requirements.

The roller bearing design lowers friction and wear, reducing lubrication needs and maintenance downtime. Across high-cycle production, expect improved throughput and fewer part replacements, contributing to a favorable ROI when upgrading older guide-block solutions. Track uptime gains and maintenance intervals to quantify the savings accurately over the product’s lifespan.