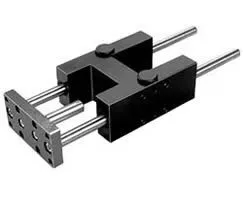

Norgren QA/8050/61/500 Guide Block Roller Bearing - 50 mm Bore

Part Number: QA/8050/61/500

Quick Summary

QA/8050/61/500 guide block roller bearing delivers precise linear motion for automation equipment. Engineers often struggle with misalignment and wear in long-stroke actuators, leading to downtime and rising maintenance costs. This model supports industry-standard safety and protection expectations, with CE compliance, IP-rated protection, and considerations relevant to SIL-oriented safety cycles. For system integrators and OEMs, the combination of robust design and straightforward mounting reduces installation risk. The solution also aligns with compatible Norgren cylinders and legacy systems, delivering predictable performance, easier maintenance, and improved total cost of ownership through longer service intervals and consistent repeatability.

Product Information

Cylinder diameter

50 mm

Brand

IMI Norgren

Feature: 50 mm bore and 500 mm stroke provide robust, precise travel with high stiffness. Business Impact: Reduces misalignment and unintended deflection, cutting wear and downtime in automated lines. Application: Packaging, pick-and-place, and fixture actuation where repeatability matters. Feature: Roller bearing guide block design minimizes friction and wear under high-cycle conditions. Business Impact: Extends service intervals and lowers maintenance costs while preserving accuracy. Application: High-speed transfer systems and CNC integration where smooth motion is critical. Feature: Compatibility with Norgren actuation portfolios enables quick integration and standardized maintenance. Business Impact: Reduces design time and BOM complexity, accelerating time-to-market. Application: OEM automation cells and retrofit projects. Feature: Easy installation with standard mounting patterns and available CAD/Installation resources. Business Impact: Speeds up commissioning, reduces error during assembly, and supports scalable configurations. Application: Any retrofit or new-build project requiring reliable linear motion. Feature: Downloadable CAD and installation guides streamline engineering workflows. Business Impact: Improves design accuracy and inline documentation compliance, lowering project risk. Application: Mechanical design, engineering validation, and supplier audits. Industry insights: Standardized interfaces across the IMI Norgren family simplify maintenance, spare parts planning, and cross-compatibility across models.

Get a Quick Quote for a Norgren QA/8050/61/500

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8050/61/500?

Enquire Now

FAQs

Installing the QA/8050/61/500 guide block on an existing Norgren actuation setup is straightforward thanks to its standard mounting pattern and compatible bore size. Begin by aligning the block with the guide rail, securing with the recommended fasteners, and connecting to the actuator rod. Refer to the Installation Guide PDF for torque specs and alignment tips to minimize wear and ensure repeatable motion.

In high-cycle packaging, the 50 mm bore and 500 mm stroke provide robust stiffness and predictable travel. The roller bearing guide reduces side loads and wear, improving repeatability under frequent starts and stops. For best results, validate with the CAD model in your assembly and ensure proper lubrication and alignment per the Installation Guide.

Yes, the QA/8050/61/500 is designed to integrate with Norgren's IMI precision cylinder families and standard mounting interfaces. Its 50 mm bore and 500 mm stroke maintain consistent centerline alignment when paired with compatible actuators, enabling modular assemblies. Always verify mounting pattern and connect via the CAD resources to avoid misfit.

While specification sheets emphasize compatibility and performance, most automation components, including this Norgren unit, align with CE safety requirements and typical IP protection levels in industrial installations. For safety-critical cycles, consider SIL-related safety guidelines and confirm with your compliance team and the product datasheet.

By reducing misalignment and wear, this guide block can extend service intervals, lower unplanned downtime, and simplify replacements. The 50 mm bore/500 mm stroke design supports longer travel with stable repeatability, while downloadable CAD and installation guides streamline deployment—delivering faster time-to-market and lower total cost of ownership.