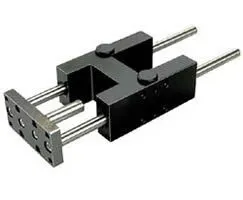

Norgren QA/8063/51/100 Guide block - 63 mm bore

Part Number: QA/8063/51/100

Quick Summary

Norgren QA/8063/51/100 guide block delivers precise linear actuation for automation systems. Engineers often face misalignment and wear in plain bearing guides, which can cause downtime and maintenance spikes. While this data lists a 63 mm bore and a 100 mm stroke, buyers should verify compatibility with industry standards such as CE, IP ratings, and SIL where applicable as part of supplier documentation. This combination supports reliable automation, with easy CAD integration and familiar mounting patterns, translating into faster design cycles and reduced field customization costs.

Product Information

Cylinder diameter

63 mm

Brand

IMI Norgren

The 63 mm bore and 100 mm stroke define the fundamental actuation envelope, enabling predictable speed and load handling for high-cycle applications in assembly lines and machine tending. This feature translates into measurable business impact: improved cycle times and consistent positioning, which reduce scrap and rework. In practice, the guide block’s plain bearing style minimizes friction and wear, extending service life in demanding environments and lowering maintenance frequency. Installation and integration are streamlined by availability of CAD models and an official installation guide, enabling engineers to validate fitment, mounting positions, and clearance early in the design phase. The component’s compatibility with Norgren’s ecosystem simplifies spare parts planning and depot stocking, supporting lean inventory and faster repairs. Overall, this solution addresses common objections about retrofit risk and downtime by delivering a robust, easy-to-integrate pneumatic actuation option with predictable performance.

Get a Quick Quote for a Norgren QA/8063/51/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8063/51/100?

Enquire Now

FAQs

This guide block uses standard mounting patterns compatible with IMI Norgren actuators, and benefits from the available CAD models and installation guide. Before installation, confirm the mounting surface is clean, aligned, and free of debris to prevent misalignment. Check clearances around the bore and stroke to avoid contact with adjacent components, and verify that the chosen mounting hardware matches the cylinder pattern specified in the installation guide.

The 63 mm bore sets the pneumatic actuation capacity, influencing forces and stroke consistency, while the 100 mm stroke defines the linear travel available for end-of-arm tooling or fixtures. Together they enable stable repeatability and predictable motion profiles in high-cycle tasks. In practical terms, this translates to reliable cycle times, controlled acceleration, and minimized position error at the end of stroke.

Yes, for applications like part presentation, pick-and-place, and machine tending where compact, robust guidance is required. The plain bearing guide block design delivers durable wear resistance in repetitive cycles, and the 63 mm bore with 100 mm stroke offers a balanced actuation envelope for tight spaces. Consider verifying IP/CE expectations and supplier documentation for your specific automotive environment.

While the data provided does not specify certifications, procurement should confirm applicable standards such as CE marking, IP ratings, and SIL safety integrity levels with the supplier or distributor. Verify that the installation guide and CAD data reflect the exact model QA/8063/51/100, and request any third-party test reports or certificates relevant to your plant safety and quality programs.

Expect reduced downtime due to the plain bearing design’s low friction and longer wear life in high-cycle scenarios. Availability of CAD and installation resources speeds commissioning and future maintenance. Stocking the model QA/8063/51/100 alongside compatible Norgren components can simplify spares planning, shorten repair times, and contribute to a lower total cost of ownership in automated lines.