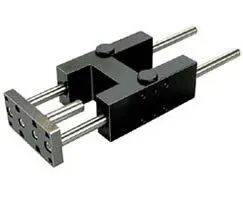

Norgren QA/8063/51/160 Guide Block - 63 mm Bore

Part Number: QA/8063/51/160

Quick Summary

Norgren QA/8063/51/160 guide block provides precise linear motion for automation systems across packaging, assembly, and machining applications. In tight layouts, wear, misalignment, and restricted stroke can throttle throughput, making consistency hard to achieve. This family supports CE compliance for European facilities, and often offers IP-rated variants and SIL-ready configurations for safety-critical lines. For procurement teams, the design translates to predictable interchangeability with standard 63 mm bore cylinders, reducing spare parts inventory, while CAD-ready data accelerates engineering work and enhances uptime. The result is a streamlined path from concept to production, with measurable improvements in accuracy, maintenance timelines, and total cost of ownership across diverse industrial environments.

Product Information

Cylinder diameter

63 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The 63 mm bore provides robust actuation with clean, repeatable motion, reducing wear-related drift and extending service intervals in high-cycle packaging equipment. This directly improves line uptime and product consistency in assembly cells and conveyance stages. Feature → Business Impact → Application: The plain bearing guide block geometry minimizes friction without complex lubrication regimes, delivering smoother motion and simpler maintenance in CNC tooling and automated pick-and-place systems. Feature → Business Impact → Application: A 160 mm stroke enables longer travel within a compact footprint, reducing additional linkage components and preserving valuable machine real estate in tightly packaged automation lines. Feature → Business Impact → Application: CAD-ready data and the included installation guide shorten engineering time, minimize integration risk, and accelerate commissioning, especially for retrofits or multi-vendor lines. Feature → Business Impact → Application: Interchangeability with standard 63 mm bore components lowers inventory costs and simplifies spare-part procurement for OEMs and maintenance teams. Feature → Business Impact → Application: The Norgren heritage supports reliability under varied industrial conditions; you gain predictable performance across packaging, material handling, and automated manufacturing domains. Additional considerations: lubrication intervals and proper alignment practices mitigate wear in plain bearings, while the CAD data supports precise fit checks prior to purchase.

Get a Quick Quote for a Norgren QA/8063/51/160

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8063/51/160?

Enquire Now

FAQs

QA/8063/51/160 is designed for standard 63 mm bore assemblies commonly used in modern automation lines. The CAD data and the Installation Guide simplify retrofit or new-install projects, ensuring proper alignment and mounting interfaces. When integrating, verify mounting bolt patterns, stroke alignment, and end-plate tolerances to minimize misalignment-related wear and maximize repeatability.

The 63 mm bore provides a sturdy actuation profile while the 160 mm stroke enables extended travel within a compact footprint. This combination reduces the need for auxiliary linkages, improves positioning accuracy, and shortens cycle times in packaging and assembly lines. For high-frequency packaging, the configuration supports repeatable motion and lower maintenance due to smoother guidance.

For harsh environments or certified installations, seek IP-rated variants and SIL-ready configurations typical for this product family. CE compliance supports European market requirements, while selecting IP ratings appropriate to dust and moisture exposure helps protect guidance surfaces and seals. Confirm environmental specifications with the supplier and consider protective housings or seals for extreme conditions.

Begin with clean, parallel mounting surfaces and verify that the guide block aligns with the mating slide or rail. Use calibration shims if needed to ensure perpendicularity and minimize side-loading. Secure endplates with appropriate fasteners, then run a low-speed test cycle to confirm smooth travel and repeatable stop positions before ramping to production speeds.

Plain bearing guide blocks require regular lubrication intervals aligned with your duty cycle and environmental conditions. Regular inspection for wear, pitting, or scoring on bearing surfaces is advised. The predictable, standardized bore/stroke improves spare-parts planning, reduces downtime during maintenance, and lowers total cost of ownership through longer service life and easier part replacement.