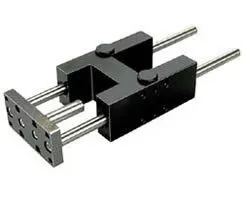

Norgren QA/8063/51/200 Guide Block – 63mm Bore

Part Number: QA/8063/51/200

Quick Summary

Norgren QA/8063/51/200 guide block provides precise linear motion for automation and control systems across packaging and manufacturing lines. Engineers often contend with misalignment, wear, and downtime that erode throughput; this plain bearing style minimizes friction, enhances smooth travel, and extends service intervals. Typical certifications to verify for industrial actuators include CE marking, IP-rated protection for challenging environments, and SIL considerations in safety-critical lines. With CAD data, installation guidance, and straightforward mounting options, this block delivers faster integration, lower total cost of ownership, and more reliable operation in demanding factories.

Product Information

Cylinder diameter

63 mm

Brand

IMI Norgren

Feature: 63 mm cylinder diameter with a 200 mm stroke. Business Impact: Delivers predictable travel, consistent actuation force, and extended reach for components handling in confined spaces, reducing cycle times and misalignment. Application: Suitable for end-of-line packaging, pick-and-place, and material-handling tasks where space is at a premium.

Feature: Plain bearing guide block design. Business Impact: Lower friction and wear, improving uptime and extending maintenance intervals in high-cycle environments. Application: Continuous production lines and automated assembly where lubricant retention and smooth motion matter.

Feature: CAD availability and installation documentation. Business Impact: Speeds design-in and reduces engineering time, enabling faster deployment and fewer on-site changes. Application: New machine builds and retrofits where fast integration with existing Norgren ecosystems is essential.

Feature: Robust mounting compatibility with Norgren accessories. Business Impact: Simplifies installation, minimizes compatibility risk, and supports scalable upgrades. Application: Retrofit projects and modular automation platforms across multiple lines.

Feature: Compliance-ready design considerations. Business Impact: Aligns with standard industrial practices, easing risk management and certification checks. Application: Regulated or safety-critical environments where CE conformity and appropriate IP protections are expected.

Feature: Plain bearing guide block design. Business Impact: Lower friction and wear, improving uptime and extending maintenance intervals in high-cycle environments. Application: Continuous production lines and automated assembly where lubricant retention and smooth motion matter.

Feature: CAD availability and installation documentation. Business Impact: Speeds design-in and reduces engineering time, enabling faster deployment and fewer on-site changes. Application: New machine builds and retrofits where fast integration with existing Norgren ecosystems is essential.

Feature: Robust mounting compatibility with Norgren accessories. Business Impact: Simplifies installation, minimizes compatibility risk, and supports scalable upgrades. Application: Retrofit projects and modular automation platforms across multiple lines.

Feature: Compliance-ready design considerations. Business Impact: Aligns with standard industrial practices, easing risk management and certification checks. Application: Regulated or safety-critical environments where CE conformity and appropriate IP protections are expected.

Get a Quick Quote for a Norgren QA/8063/51/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8063/51/200?

Enquire Now

FAQs

To install, refer to the Installation Guide (PDF) provided by Norgren and use standard ISO/metric mounting hardware. Verify mounting clearance, align the block with the rail or surface, and secure with appropriate bolts. Use the CAD data to confirm envelope and fit, then connect any required end stops and lubrication intervals. This approach minimizes misalignment and speeds up integration into existing automation setups.

The unit features a 63 mm cylinder diameter and a 200 mm stroke, delivering a balanced combination of force, travel, and compactness. This geometry supports consistent actuation in high-cycle applications, reduces travel error, and enhances repeatability across repetitive tasks such as pick-and-place and transfer operations. The plain bearing design further lowers friction, contributing to stable performance over life cycles.

Yes. The 63 mm bore and 200 mm stroke provide a versatile reach for packaging and assembly tasks, while the guide block’s plain bearing design supports smooth motion under repetitive cycles. With readily available CAD data and installation guidance, engineers can rapidly model-in the block, ensuring reliable actuation on conveyor interfaces, carton handling, and product transfer stations.

For industrial actuators like this guide block, CE marking and appropriate IP protection are common expectations in many regions, along with safety considerations such as SIL in safety-critical lines. It is best to confirm the exact certifications on the latest datasheet or through the supplier’s downloads, as certification coverage can vary by configuration and region.

The plain bearing design reduces friction and wear, contributing to longer service intervals and reduced downtime. Compatibility with CAD data accelerates design-in, lowering engineering hours and speeding time-to-market. In retrofit projects, rapid integration can shorten validation cycles, while predictable actuation improves line throughput and total cost of ownership.