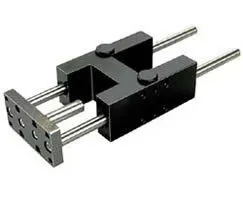

Norgren QA/8063/51/250 Guide block plain bearing style - 63 mm bore

Part Number: QA/8063/51/250

Quick Summary

Norgren QA/8063/51/250 guide block provides precise linear guidance for pneumatic actuators in automation systems. This design helps eliminate end-of-stroke misalignment and uneven wear that can derail production schedules. In practice, engineers contend with motion chatter, binding, and maintenance downtime; site-approved, robust guide blocks reduce those risks. In typical industrial deployments, CE marking, IP ratings, and SIL safety considerations are essential for safe, compliant operation in automated lines. By delivering reliable guidance with a compact footprint, this solution supports higher uptime and predictable cycles. The integration with standard mounting interfaces and compatible CAD/download resources further streamlines procurement and installation, enabling faster project ramp-ups and lower total cost of ownership.

Product Information

Cylinder diameter

63 mm

Brand

IMI Norgren

63 mm bore and 250 mm stroke deliver ample travel to accommodate mid-stroke actuators while maintaining tight positional accuracy. This translates to fewer intermediate linkages, reducing assembly complexity and cycle time in pick-and-place and fixture positioning tasks. In real-world lines, that means higher throughput and more consistent repeatability in automation and control systems. Plain bearing guide blocks run with low friction and reduced stick-slip, extending service life in dusty or damp factory floors. The improved wear resistance lowers maintenance intervals and replacement costs; operators gain steadier motion with fewer recalibrations. The compact, standard-mounted block integrates with common mounting patterns, reducing installation time and risk of misalignment. Compatibility with existing equipment accelerates deployment across plants and lines. Documentation and CAD resources streamline the engineering workflow, ensuring correct hole spacing, fasteners, and alignment. In broader terms, this solution fits robotics, packaging, and assembly applications within automation & control systems, delivering predictable performance and cost-effective operation.

Get a Quick Quote for a Norgren QA/8063/51/250

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8063/51/250?

Enquire Now

FAQs

The QA/8063/51/250 guide block is designed for compatibility with standard mounting patterns common in automation and control systems. This enables straightforward integration with existing pneumatic actuators and fixtures. When planning installation, verify hole spacing and fastener sizes from the Installation Guide PDF to ensure a precise, secure fit that minimizes misalignment and vibration during operation.

The product features a 63 mm bore and a 250 mm stroke, delivering ample travel for typical pick-and-place and linear positioning tasks. These dimensions support reliable guidance for mid-range actuator travel while maintaining tight positional accuracy, reducing the need for auxiliary linkage and simplifying maintenance in automation lines.

In industrial deployments, IP ratings are a key consideration for protecting moving components from dust and moisture. While the guide block design supports robust operation in many factory environments, always cross-check the exact IP rating requirements for your application and region. The product family typicals emphasize durability and reliable performance in automation and control systems.

Begin by confirming mounting hole patterns and alignment with your actuator and fixture. Use the Installation Guide PDF for step-by-step guidance, including fastener selection, alignment checks, and calibration procedures. If CAD models are available, download them to validate spatial fit before assembly, which helps prevent misalignment and reduces commissioning time.

Plain bearing guide blocks offer low friction and durable guidance, but routine inspection is prudent in dusty or damp environments. Check for signs of wear, verify alignment, and follow your maintenance schedule to prevent end-of-life wear. Depending on operating conditions, periodic lubrication and inspection can extend service life and maintain repeatable motion in automation systems.