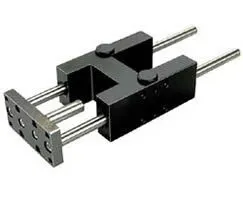

Norgren QA/8063/51/320 - Guide block 63mm bore

Part Number: QA/8063/51/320

Quick Summary

QA/8063/51/320 is a guide block for precise linear actuation in automation and packaging lines. Engineers often wrestle with misalignment, limited stroke options, and downtime from wear in guide-block assemblies. Typical certifications in this class include CE marking and IP-rated environments, with SIL considerations depending on your control architecture. Using this model helps cut downtime, improve repeatability, and simplify field installations across 63 mm bore systems. Primary value is reduced maintenance costs and predictable performance, while CAD downloads and installation guides streamline commissioning. In practice, specifying a 63 mm bore guide block like QA/8063/51/320 aligns with standard automation layouts and reduces engineering time.

Product Information

Cylinder diameter

63 mm

Brand

IMI Norgren

63 mm bore and 320 mm stroke establish a reliable travel envelope for consistent motion across automation lines. The plain bearing guide block minimizes friction and wear, delivering smoother actuation and tighter positional repeatability under high-cycle operation. This translates to longer service intervals, reduced maintenance costs, and fewer stoppages during critical manufacturing steps such as assembly, labeling, and packaging. CAD data and the Installation Guide PDF are integrated into the product experience, accelerating engineering validation and field commissioning. By validating fit in the digital stage, technicians can pre-assemble components, plan mounting points, and avoid costly rework on the shop floor. The availability of downloadable CAD models also supports automated documentation and bill-of-material alignment with ERP systems. Standard bore compatibility simplifies spare-part management and retrofit projects. With a common 63 mm bore across this guide block family, technicians can swap components with minimal downtime and stock fewer unique parts. The result is faster changeovers, easier supplier coordination, and improved alignment with compatible actuators and mounting accessories in automation setups. Durability and low-maintenance design reduce lubrication demands and extend service life in dusty or damp environments. The plain bearing style is resilient to contaminants when paired with proper seals and mounting, while the robust stroke length sustains performance across similar cycles. In practice, this translates to lower total cost of ownership and steadier output in continuous production lines. From installation to operation, the model delivers measurable ROI through uptime gains and predictable performance. The combination of 63 mm bore, 320 mm stroke, and accessible documentation decreases engineering effort, shortens time-to-value, and supports compliance practices in regulated environments. For teams looking to optimize throughput without overhauling existing infrastructure, this guide block represents a prudent, scalable choice.

Get a Quick Quote for a Norgren QA/8063/51/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8063/51/320?

Enquire Now

FAQs

The QA/8063/51/320 uses a standard 63 mm bore guide block design and can be mounted on compatible actuator assemblies with common mounting patterns. Start by consulting the Installation Guide PDF and verify alignment before tightening mounting bolts. Use the CAD model to validate clearances and ensure correct stroke coverage before final assembly.

Key specs include a 63 mm bore and a 320 mm stroke, with a plain bearing guide block for low friction. These features contribute to smoother motion, improved repeatability, and reduced wear in high-cycle applications. When selecting for high-speed lines, verify mounting rigidity and alignment to maintain consistent performance across cycles.

Yes. The 63 mm bore and 320 mm stroke are well-suited for repetitive tasks in packaging and material handling, where consistent travel and positioning accuracy are critical. The plain bearing design minimizes maintenance while providing durable guidance, helping sustain throughput on continuously operating lines with tight tolerances.

Product data references typical industry considerations like CE marking and IP ratings, but formal certifications should be confirmed with the supplier for your region and application. Always verify required standards (CE, IP, SIL) with your compliance team and consult the supplied CAD/Installation resources to ensure proper integration.

Expect ROI from reduced downtime and longer service intervals due to low-friction plain bearings and reliable stroke. CAD data and installation guides accelerate commissioning, lowering engineering effort. Availability of downloadable resources supports faster procurement, BOM accuracy, and smoother integration with existing automation infrastructure.