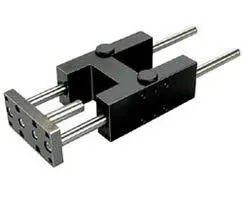

Norgren QA/8063/51/400 Guide block - 63mm bore, 400mm stroke

Part Number: QA/8063/51/400

Quick Summary

QA/8063/51/400 is a precision guide block cylinder designed for reliable linear actuation in automation and tooling applications. It addresses the persistent challenge of maintaining accurate stroke and alignment in compact footprints, especially under cyclic loads. The unit features a 63 mm bore and a 400 mm stroke, delivering long travel with predictable motion. While this product integrates seamlessly with Norgren controls and standard mounting interfaces, verify the exact certification status for your application with the supplier. In practice, many users seek CE compliance and IP-rated variants within this family to meet safety and environmental requirements. Overall, this cylinder supports higher throughput, reduced maintenance intervals, and lower total cost of ownership when matched with proper control logic and CAD data.

Product Information

Cylinder diameter

63 mm

Brand

IMI Norgren

Feature: 63 mm bore and 400 mm stroke deliver extended travel from a compact cylinder. Business impact: enables greater axial travel within a small footprint, reducing the need for additional actuators and enabling faster cycle times. Application: pick-and-place and assembly lines where space is at a premium and precise reach is required. Feature: Plain bearing guide block design provides smooth, low-friction motion with predictable wear characteristics. Business impact: reduces maintenance intervals, extends service life, and lowers operating costs. Application: high-cycle automation where consistent alignment is critical for part quality. Feature: Compatibility with CAD data and installation guides accelerates integration. Business impact: shortens lead times, minimizes commissioning risk, and supports standardization across lines. Application: retrofits and new lines that leverage existing Norgren or third-party controls. Feature: Standard mounting interfaces and robust construction improve uptime. Business impact: minimizes downtime during replacements and simplifies field service. Application: robotics cells and packaging lines operating in environments with vibration and variable loads. Feature: Support for high-cycle, high-precision actuation in harsh environments. Business impact: improves throughput and yields, while maintaining repeatable performance. Application: automotive, electronics assembly, and material handling. Industry insight: aligning cylinder selection with stroke, bore, and guide-block design directly correlates to total cost of ownership and downtime reduction in lean manufacturing.

Get a Quick Quote for a Norgren QA/8063/51/400

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8063/51/400?

Enquire Now

FAQs

QA/8063/51/400 uses standard guide block mounting compatible with Norgren control interfaces and common ISO mounting patterns. To install, align the bore with the actuator axis, secure with the supplied mounting bolts, and connect the control valve or sensor wiring per the Installation Guide. The CAD data and installation instructions help ensure correct alignment, torque, and travel limits, reducing commissioning time and risk of misalignment.

The 63 mm bore defines the piston diameter, while the 400 mm stroke indicates the travel length. This combination provides extended actuation within a compact envelope, supporting longer reach and faster cycle times in automated lines. The plain bearing guide block design minimizes side-load effects and maintains repeatability across cycles, which is critical for consistent part handling and positioning.

Yes, when matched with proper control logic and mounting, the 63 mm bore and 400 mm stroke configuration supports high-cycle packaging and light-to-medium robotics tasks. The plain bearing guide block offers smoother motion and reduced wear, which helps maintain uptime and predictable repeatability under repetitive cycles. Always validate with your cycle rate, load profile, and environmental conditions.

For regulated environments, verify CE conformity and any IP-rated variants within the Norgren family that match your enclosure and wash-down requirements. Confirm that the exact QA/8063/51/400 configuration you order includes the desired certifications and environmental ratings, and reference the supplier datasheet and Installation Guide to ensure compliance with your safety and regulatory standards.

The plain bearing guide block design reduces friction wear and prolongs service intervals, lowering maintenance costs and downtime. A longer, stable stroke improves process efficiency, reducing cycle times and part rejection rates. Access to CAD data and installation guides speeds up commissioning, supporting a faster path to return on investment through improved throughput and lower lifecycle costs.