Norgren QA/8063/61/100 Pneumatic Cylinder - 63 mm Bore

Part Number: QA/8063/61/100

Quick Summary

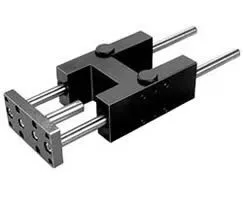

The Norgren QA/8063/61/100 pneumatic cylinder provides precise linear actuation for automation and control systems. Engineers often face misalignment, uneven wear, and challenging install when selecting compact actuators, leading to downtime and maintenance costs. In this class, CE compliance and IP ratings for environmental protection, along with SIL considerations for safety-critical tasks, are key benchmarks to verify. This unit leverages a guide block roller bearing style and a 63 mm bore with a 100 mm stroke to deliver smooth, repeatable motion in confined spaces. The combination supports reliable performance, easy compatibility with standard mounting catalogs, and a quick-installation workflow, driving efficiency gains for industrial automation projects and higher equipment uptime.

Product Information

Cylinder diameter

63 mm

Brand

IMI Norgren

63 mm bore and 100 mm stroke provide precise, repeatable motion in tight work envelopes, enabling compact layouts without sacrificing stroke length. This combination supports high-speed cycling and predictable positioning in automation cells, packaging lines, and assembly stations. By leveraging the Norgren QA/8063/61/100, engineers gain a consistent motion profile across operating temperatures and load conditions, simplifying control strategies and reducing the need for oversized actuators in the same footprint. Guide block roller bearing style reduces friction and side-load effects, delivering smoother movement and longer service life in high-cycle environments. The design minimizes stiction and wear, lowering maintenance intervals and spare-parts spend while preserving repeatability. This matters most in process automation and material handling, where even small improvements in reliability translate into meaningful uptime gains and reduced scrap. CAD models and an Installation Guide are available to speed integration and cut commissioning time. Clear dimensional data, mounting hole patterns, and port locations help designers validate fit before procurement, while installers benefit from a straightforward setup using standard Norgren accessories. The robust documentation supports quick-start testing, reducing changeover time on production lines. Mounting compatibility with common Norgren accessories and standard industry interfaces simplifies retrofits, upgrades, and expansions. The actuator's compact form factor and verified mounting patterns help ensure alignment with existing frames and rails, preventing misalignment that can cause seal wear or accelerated strokes. Quick-connect fittings and familiar cylinder circuitry further streamline installation and maintenance in busy automation environments. Regulatory readiness and field reliability address procurement concerns about certification and uptime. While CE compliance and IP protection are design expectations for this class of component, verification through the provided CAD and installation materials helps assurance during supplier audits. Coupled with easy sourcing and a local service network, the QA/8063/61/100 delivers predictable performance and favorable total cost of ownership for automation projects. This supports faster ROI and lower lifecycle risk.

Get a Quick Quote for a Norgren QA/8063/61/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8063/61/100?

Enquire Now

FAQs

QA/8063/61/100 follows standard Norgren mounting patterns, which simplifies retrofits and new designs. Before integration, check hole spacing, end-plate compatibility, port sizes, and cylinder alignment using the CAD model and Installation Guide. This reduces installation time, minimizes misalignment risk, and ensures reliable operation with existing frames, brackets, and quick-connect fittings across automation projects.

The cylinder provides a 63 mm bore and 100 mm stroke, suitable for precise linear actuation in automation cells. While exact operating pressure and speed ranges depend on system design, the 63 mm bore offers a defined piston area for predictable force, and the 100 mm stroke supports adequate travel in compact footprints. Refer to CAD data and installation guide for detailed performance curves.

Yes, its compact 63 mm bore with a 100 mm stroke and smooth guide block roller bearing movement are well-suited to packaging, labeling, and assembly tasks. The cylinder's compact footprint allows tight line layouts, while reliable motion supports accurate positioning and repeatability on fast-moving conveyors and pick-and-place operations. Coupled with Norgren accessories, it integrates smoothly into existing packaging systems.

Key considerations for certification include CE compliance for safety, and IP ratings for environmental protection, plus SIL considerations for safety-critical applications. While the official documentation should confirm the exact status, verifying these aspects during supplier audits ensures regulatory alignment and reduces risk in automated environments.

Maintenance impact centers on long service life from the guide block roller bearing design, which lowers wear and downtime. Availability of CAD data and installation guides speeds commissioning, reducing labor costs. Across a typical automation project, this translates to shorter downtime, faster changeovers, and a favorable total cost of ownership through reliable performance and easier sourcing. This supports faster ROI and lower lifecycle risk.