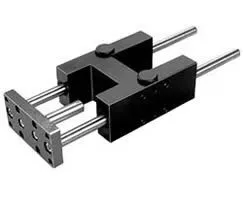

Norgren QA/8063/61/320 Guide Block Roller Bearing - 63 mm Bore

Part Number: QA/8063/61/320

Quick Summary

QA/8063/61/320 guide block roller bearing style cylinder delivers precise linear motion for automated manufacturing and packaging lines. Engineers frequently face misalignment, wear, and downtime when guides are undersized or incompatible with control systems. These solutions improve reliability through CE compliance considerations and reliable IP-rated protection, with SIL variants for safety-critical lines. By standardizing fit and performance, you can shorten design time and reduce total cost of ownership across automation cylinders. In practice, this model translates to easier integration in automation systems, enabling smoother operation, higher uptime, and a clearer path to scalable production workflows.

Product Information

Cylinder diameter

63 mm

Brand

IMI Norgren

The 63 mm bore and 320 mm stroke provide a robust foundation for dependable travel and reach in conveyors, pick-and-place stations, and assembly lines. This combination supports precise stop positions and repeatable motion, reducing cycle variability and improving overall process control. In practice, these specifications translate to higher first-pass yield and consistent throughput across shifts. The guide block with roller bearings minimizes friction and wear, delivering measurable energy savings and longer component life. This design lowers maintenance costs and reduces the risk of unexpected outages in high-cycle environments, particularly in packaging and material handling tasks that demand repeatable accuracy. Compatibility and installation advantages are clear: standard mounting patterns and readily available Norgren accessories simplify design-in and retrofit efforts, while CAD downloads and an installation guide PDF accelerate validation and field deployment. Engineers report faster setup, reduced engineering change orders, and fewer integration errors when substituting legacy guide systems. Performance and compliance considerations are reinforced by the bore-stroke pairing, enabling precise acceleration profiles and stable operation even in compact automation cells. The rugged guidance system contributes to reliability in challenging environments when paired with proper sealing and mounting. These factors collectively reduce downtime, improve OEE, and support long-term lifecycle costs. Industry context favors standardized actuation solutions like QA/8063/61/320 to simplify maintenance planning, inventory management, and cross-line interoperability, delivering a compelling ROI for modern manufacturing operations.

Get a Quick Quote for a Norgren QA/8063/61/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8063/61/320?

Enquire Now

FAQs

QA/8063/61/320 is designed to fit standard Norgren mounting patterns and is designed to work with common mounting accessories from the Norgren family. For a streamlined design-in, use the available CAD download and the Installation Guide PDF to verify clearances, fasteners, and mounting face compatibility prior to procurement.

Key specifications include a 63 mm cylinder bore and a 320 mm stroke, with a guide block roller bearing style for smooth guidance. The product is marketed as IMI Norgren, in the Automation & Control Systems category, with a 63 mm bore clearly listed in the product detail. The CAD and installation resources support quick validation.

Yes. The 63 mm bore and 320 mm stroke provide adequate reach and force for many packaging and pick-and-place applications. The guide block roller bearing design supports smooth, repeatable motion, which is essential for high-throughput packaging and precision assembly, helping to maintain product quality and reduce cycle time in automated cells.

Industry expectations for similar Norgren products often include CE marking and general IP-rated protection, with SIL variants available for safety-critical lines. For confirmed certifications on this specific model, consult the Installation Guide PDF and the CAD data download to verify compliance details for your regional regulatory requirements.

The roller-bearing guidance reduces wear and friction, lowering energy consumption and extending service life, which translates to lower maintenance costs and fewer unplanned outages. The CAD resources and installation guide shorten design and commissioning times, accelerating project ROI by reducing downtime during setup and future upgrades.