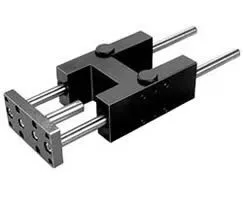

Norgren QA/8063/61/400 Guide Block Roller - 63 mm Bore

Part Number: QA/8063/61/400

Quick Summary

QA/8063/61/400 is a guide block roller actuator designed for precise linear motion in automation and control systems. Engineers often struggle with misalignment and stiction in guide blocks, which can inflate cycle times and increase maintenance. CE conformity is common for EU markets, and where applicable IP protection and SIL considerations help meet industrial safety and environmental requirements. With a 63 mm bore and a 400 mm stroke, this model delivers extended travel in a compact footprint, accelerating design and reducing hardware counts. Verified compatibility with Norgren mounting patterns and available CAD resources supports faster procurement and seamless integration into existing automation architectures.

Product Information

Cylinder diameter

63 mm

Brand

IMI Norgren

Feature: The QA/8063/61/400 uses a 63 mm bore and a 400 mm stroke for substantial travel within a compact package. Business impact: This reduces module count and simplifies machine layout, increasing line density and throughput. Application: Ideal for automation stations, clamping setups, and conveyor transfer points in manufacturing lines. Feature: The guide block roller bearing style delivers low friction and high stiffness. Business impact: The result is reduced wear, lower dynamic backlash, and longer maintenance intervals. Application: Suitable for precision pick-and-place, metrology stages, and robot-guided assembly in electronics and automotive lines. Feature: Compatible with standard Norgren mounting patterns and access to CAD resources. Business impact: Engineers accelerate design iterations with readily available CAD files and installation guides, shortening commissioning. Application: Fits into existing Norgren manifolds and supports rapid integration with PLCs and servo systems. Feature: Availability of CAD and Installation Guide content expedites on-site setup. Business impact: Reduces field errors and speeds commissioning. Application: Useful during machine retrofits and new line builds. Feature: Robust guide block minimizes deflection under load. Business impact: Improves repeatability and yields in high-precision assembly. Application: Packaging, electronics assembly, and medical device manufacturing. Feature: Norgren branding ensures global support and spare-part availability. Business impact: Enables long-term serviceability and uptime. Application: Global operations requiring robust motion control solutions.

Get a Quick Quote for a Norgren QA/8063/61/400

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8063/61/400?

Enquire Now

FAQs

Begin by confirming mounting pattern compatibility with your frame, then mount the guide block onto the rail, ensure the roller bearings rotate freely, and connect the air supply with appropriate filtration and lubrication. Align to minimize side loads, torque fasteners to specification, and perform a calibration check to verify smooth travel and repeatability.

The 63 mm bore provides adequate actuation force for common automation tasks, while the 400 mm stroke offers extended travel per cycle. This combination reduces the need for multiple actuators, enables longer strokes across conveyors or clamps, and translates into higher throughput with fewer transfer points.

Yes. The model is designed to align with standard Norgren mounting patterns and benefits from readily available CAD models and installation documentation, enabling quick retrofit or seamless integration into current automation architectures.

Check EU CE conformity for European installations and verify any IP ratings if the unit operates in dusty or moist environments. For safety-critical lines, review applicable SIL standards and consult the product documentation for region-specific certs and compliance requirements.

ROI benefits come from reduced cycle times, lower maintenance due to fewer moving parts, and improved repeatability. The extended travel allows denser layouts and faster commissioning, with payback dependent on line speed, downtime costs, and parts availability across facilities.