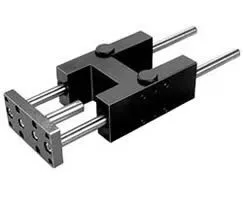

Norgren QA/8063/61/50 Guide Block - 63 mm Bore

Part Number: QA/8063/61/50

Quick Summary

QA/8063/61/50 guide block delivers reliable linear actuation for compact automation systems. Engineers often struggle with misalignment, friction, and inconsistent stroke in tight spaces. Designed to meet CE compliance, with IP-rated protection options and SIL safety integration available in system configurations, it supports safe, regulatory-ready installations. This 63 mm bore, 50 mm stroke pneumatic actuator reduces downtime and wear, improving repeatability and tool life in high-cycle environments. By aligning with your existing Norgren components, it offers fast installation, CAD access, and scalable performance for growing production lines, while supporting easy maintenance and predictable maintenance windows. This translates into higher throughput and a lower total cost of ownership.

Product Information

Cylinder diameter

63 mm

Brand

IMI Norgren

63 mm bore cylinder with a 50 mm stroke provides robust actuation power within a compact footprint, enabling higher actuation density on small automation cells and robotics endpoints. The short stroke reduces travel time while maintaining repeatability, supporting fast cycle times, lower inertia, and energy savings in high-frequency lines. This combination is ideal for precise pick-and-place, fixture actuation, clamping, and spring-assisted release tasks where space and speed are critical. Guide block roller bearing guidance delivers high rigidity with low friction, improving positional accuracy across hundreds of thousands of cycles. The roller guidance resists misalignment and side loads, reducing wear, backlash, and maintenance downtime. In vibration-prone environments or temperature-variant conditions, this design maintains consistent actuation, enabling tighter tolerances and repeatable performance for automated assembly and packaging operations. Compatibility with Norgren hardware and our standardized footprint simplifies installation and spare parts management. The unit integrates with CAD data, mounting brackets, and compatible downstream cylinders, enabling rapid design-in and procurement. Installation guides and CAD downloads streamline commissioning, helping engineering teams lower project risk, shorten lead times, and scale from pilot lines to full production without rework. From a maintenance perspective, the sealed body and high-quality components minimize contamination ingress and wear, while the roller-bearing guidance reduces friction-induced heat. The actuator is engineered for reliable operation in standard industrial atmospheres, supporting predictable lifecycle costs and reduced downtime. In practice, this translates to higher machine availability, lower maintenance labor, and a lower total cost of ownership across automated lines.

Get a Quick Quote for a Norgren QA/8063/61/50

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8063/61/50?

Enquire Now

FAQs

Begin by aligning the guide block with the mounting surface using the included hardware, ensuring the bore axis matches the intended travel path. Refer to the installation guide for recommended fastener torque, alignment procedures, and pre-load guidance. Use the CAD data to verify fitment in your space, and connect to your existing pneumatic supply with appropriate filtration and lubrication for consistent performance.

A 63 mm bore delivers higher actuation force within a compact footprint, enabling stable acceleration and deceleration in tight spaces. The 50 mm stroke supports fast cycle times and repeatable positioning without excessive travel, reducing inertia and energy consumption. Together they facilitate reliable pick-and-place, clamping, and fixture actuation with tight tolerances in automated lines.

Yes, this guide block is designed to integrate with Norgren’s standard mounting patterns, mounting plates, and compatible downstream cylinders. Utilizing the same family components simplifies design-in, spare-parts planning, and maintenance. Always verify compatibility via the CAD models and check the installation guide to ensure proper interface and seal integrity when retrofitting into an existing system.

The QA/8063/61/50 guide block is designed to align with common industry standards such as CE compliance, and options exist for IP-rated protection and SIL safety integration within system configurations. These certifications help ensure regulatory compliance, operator safety, and reliability in demanding industrial environments, supporting safer and more predictable deployments across automated lines.

The combination of a robust 63 mm bore and 50 mm stroke with roller-bearing guidance yields lower wear, higher repeatability, and reduced downtime, translating into faster cycle times and longer service intervals. Availability of CAD data and installation guides shortens commissioning, while compatibility with existing Norgren components reduces spare-parts costs, contributing to a lower total cost of ownership over the life of the production line.