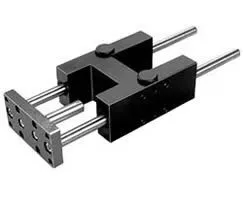

Norgren QA/8063/61/500 Pneumatic Cylinder - 63mm Bore

Part Number: QA/8063/61/500

Quick Summary

QA/8063/61/500 pneumatic cylinder delivers precise linear motion for automation and material handling in manufacturing and packaging. Operators often contend with inconsistent stroke, misalignment, and variable cycle times that increase wear on guides and reduce uptime. Designed with CE considerations in mind and compatible with SIL-rated safety architectures and IP-rated environments where required, it supports compliant, safer automation. By standardizing stroke and bore at 63 mm and 500 mm respectively, this Norgren unit reduces tuning needs and accelerates line-side installation, boosting throughput and lowering operating costs. Separate CAD and installation resources from downloads simplify engineering workflows and accelerate commissioning. This familiarity reduces integration risk with existing mounting patterns.

Product Information

Cylinder diameter

63 mm

Brand

IMI Norgren

Feature: 63 mm bore and 500 mm stroke are precisely matched to deliver reliable linear actuation across common automation tasks. Business Impact: This standardization minimizes setup variability, shortens tuning cycles, and lowers spare parts inventory by enabling common mounting patterns and replacement components. Application: Ideal for packaging lines, sorter stations, and assembly cells where repeatable travel improves cycle time. Feature: Roller bearing guide block style reduces friction for smoother motion and longer service life. Business Impact: Lower friction translates to higher cycle accuracy and reduced maintenance costs, especially in high-speed applications. Application: High-throughput packaging, pick-and-place, and conveyor-linked automation where precision and durability are critical. Feature: CAD data and installation guides are readily available for fast integration. Business Impact: Accelerates engineering workflows, reduces commissioning risk, and minimizes field errors during mounting and piping. Application: OEM line Retrofit projects and new machine buildouts. Feature: Compatibility with safety and regulatory practices, including CE considerations and SIL-friendly architectures. Business Impact: Simplifies compliance planning and safety integration, reducing project lead times. Application: Robotic cells and downstream packaging lines where safety interfaces are essential. Feature: Norgren build quality and accessible support streamline maintenance and parts replenishment. Business Impact: Improved supply chain reliability, faster service turnarounds, and lower total cost of ownership. Application: Continuous production environments and long-term capital investments.

Get a Quick Quote for a Norgren QA/8063/61/500

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8063/61/500?

Enquire Now

FAQs

QA/8063/61/500 uses standard mounting interfaces commonly found on Norgren actuators, enabling straightforward retrofits on existing frames. Confirm bolt hole spacing and alignment with the brochure or CAD data prior to ordering, and leverage the supplied installation guide for exact mounting dimensions and suggested tightening torques to avoid misalignment during commissioning.

The cylinder has a 63 mm bore and a 500 mm stroke, delivering consistent actuation force over a long travel. This combination supports stable positioning in high-cycle tasks, reduces travel variance, and simplifies control tuning. For best results, match load profiles to the 63 mm bore’s available force while planning routing for the 500 mm travel path.

Yes. The 63 mm bore with a 500 mm stroke is well-suited to packaging and material handling where repeatable travel and smooth motion are critical. The guide block roller bearing design minimizes friction, enabling higher cycle rates, longer service intervals, and lower maintenance costs in continuous operation environments.

While the data set does not list explicit certificates, the design references CE considerations and SIL-compatible interfaces for safety architectures, plus IP-environment suitability where required. Verify your specific regulatory needs with your compliance team and consult the installation guide to align wiring, control logic, and enclosure protection with local requirements.

Norgren provides CAD files and an Installation Guide to streamline engineering and commissioning. Access to these resources reduces project risk, speeds swap-outs, and improves first-time right installation. Additionally, available spare parts and service support help minimize downtime and extend the asset’s lifecycle, delivering measurable improvements in total cost of ownership.