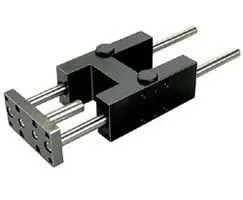

Norgren QA/8080/51/160 Guide Block - 80mm Bore

Part Number: QA/8080/51/160

Quick Summary

Norgren QA/8080/51/160 guide block is a precision actuator for linear motion in automation and control applications. Engineers often struggle with misalignment, wear, and downtime in high-cycle positioning tasks, which this design aims to mitigate through robust plain bearing guidance. While the model's 80 mm bore and 160 mm stroke deliver strong travel with a compact form, it also aligns with common industry standards that help streamline integration. Note that certifications like CE, IP ratings, and SIL are model-specific; always verify the exact variant in the datasheet. For businesses, this translates to predictable performance, easier maintenance, and reduced installation time when paired with CAD resources and installation guides.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The QA/8080/51/160 uses an 80 mm bore and a 160 mm stroke to deliver reliable travel in constrained spaces, enabling precise positioning for fixture automation and material handling. This translates to higher throughput and consistent part placement in automated lines. Feature → Business Impact → Application: Plain bearing guidance minimizes friction and wear, extending service life and reducing maintenance cycles in high-cycle operations like packaging and assembly. Feature → Business Impact → Application: Compatibility with CAD downloads and installation guides accelerates setup, cuts commissioning time, and supports accurate integration into OEM frames and automated workstations. Feature → Business Impact → Application: Compact footprint and straightforward mounting options simplify retrofits and retrofit cost reduction, allowing easier upgrades to existing automation lines without extensive reengineering. Feature → Business Impact → Application: Robust design and reliable travel improve process stability, reducing variation and improving overall yield in manufacturing environments. Industry context notes include the value of long-term reliability, ease of sourcing spare parts, and alignment with standard pneumatic automation practices.

Get a Quick Quote for a Norgren QA/8080/51/160

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/51/160?

Enquire Now

FAQs

The QA/8080/51/160 uses a guide block arrangement suitable for standard mounting in automation frames. Verify the 80 mm bore and 160 mm stroke, and reference the CAD data and Installation Guide for correct end-mconnections and mounting hardware. Check compatible adapters and selection of mounting plates to ensure precise alignment and repeatable travel.

Precision comes from the fixed 80 mm bore and 160 mm stroke combined with plain bearing guidance, which reduces friction and wear over time. For repeatability, ensure proper alignment during installation and use the provided CAD resources to model movement paths, minimizing binding and side-load effects in fixture automation.

Yes, for many medium to high-cycle packaging tasks that require consistent linear motion and compact form factors. The 80 mm bore and 160 mm stroke support reliable travel in tight spaces, while the plain bearing design helps sustain performance across frequent actuation cycles. Evaluate your cycle rate and maintenance plan to confirm fitment.

Verify model-specific certifications in the datasheet; key standards commonly relevant include CE for electrical safety and IP ratings for environmental protection, with SIL considerations only where safety functions are involved. Always confirm exact certifications for the variant you select before deployment in a regulated environment.

Leverage the CAD downloads and Installation Guide to reduce commissioning time and ensure correct mounting from the start. The robust plain bearing design minimizes wear, lowering maintenance costs, while the compact form factor can reduce enclosure footprint and material costs. For ROI, pair with compatible fittings and standard spare parts to minimize downtime during routine servicing.