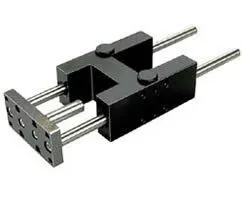

Norgren QA/8080/51/200 Guide block - 80 mm bore

Part Number: QA/8080/51/200

Quick Summary

QA/8080/51/200 is a guide block with plain bearing guidance for precise linear motion in automation and control systems. These components can suffer from misalignment and wear that disrupt line speed and push maintenance costs higher. In regulated contexts, CE compliance, IP ratings for protective enclosures, and SIL-related safety considerations are commonly required to ensure safe, reliable operation. With a robust, installation-friendly design and compatibility with standard mounting patterns, this block helps reduce spare parts inventory and downtime while delivering predictable performance across diverse automation environments. This combination supports faster procurement and consistent system design across projects. Engineers value the availability of CAD data and documentation to accelerate spec reviews.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

80 mm bore with a plain bearing guide block delivers smooth, low-friction guidance, reducing wear and improving repeatability in high-cycle automation. This translates to longer service life and fewer unplanned maintenance events, especially in packaging, machine tending, and assembly cells where precise travel is critical. The 200 mm stroke increases reach within a compact footprint, enabling longer travel without additional actuators. The business impact is reduced component counts and simplified mechanical design, lowering installation time and minimizing potential misalignment during upgrades or line changes. Applications include pick-and-place stations, conveyor transfers, and automatic inspection cells. Compatibility and installation advantages simplify deployment; the design supports standard mounting patterns and is supported by downloadable CAD data and installation guides, accelerating engineering reviews and reducing drift. This also helps procurement teams consolidate parts and shorten lead times. Reliability in high-speed cycles is enhanced by the plain bearing arrangement, offering predictable motion with fewer lubrication points than more complex guides, supporting cost-effective expansion of automation programs. Industry insights indicate CAD-ready components shorten project timelines, improve design-for-manufacture outcomes, and streamline change management across lines.

Get a Quick Quote for a Norgren QA/8080/51/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/51/200?

Enquire Now

FAQs

QA/8080/51/200 is designed with a guide block plain bearing style that aligns with common automation mounting patterns. The 80 mm bore and 200 mm stroke suit many linear actuator setups, and the included CAD drawings and installation guide simplify alignment, bracket selection, and fastener compatibility. Before installing, verify frame size, bolt circle, and stroke requirements to ensure a precise, durable fit.

Key performance parameters are an 80 mm bore and a 200 mm stroke, with a plain bearing guide block that provides smooth, low-friction motion. This setup supports repeatable positioning and reliable cycling in automation. The design minimizes stiction and wear during high-speed operations, while straightforward mounting reduces alignment errors and installation time for packaging, machine tending, and material handling applications.

Suitable for packaging lines, machine tending, and material handling, the QA/8080/51/200 offers precise travel with mitigate misalignment. The 80 mm bore and 200 mm stroke enable longer reach in compact spaces, while the plain bearing design reduces maintenance needs in high-cycle environments. Its compatibility with standard mounting and easy CAD access support fast line changes and scalable automation architectures.

Certification details are not listed in the provided data; when selecting for regulated environments, confirm with the supplier or consult the installation and CAD documentation for the latest CE, SIL, or IP status. For many automation projects, matching existing safety standards and enclosure protection levels is essential, so verify compatibility with your machine safety plan before deployment.

CAD and installation resources are provided in the product downloads. Access the CAD asset at the Norgren embedded PartCommunity link and the Installation Guide PDF at Norgren's site for QA/8080/51/200. These documents support correct orientation, mounting, fastener selection, and integration with existing Norgren components, helping reduce commissioning time and errors.