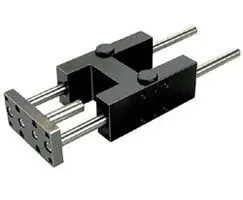

Norgren QA/8080/51/250 Guide Block - 80 mm Bore

Part Number: QA/8080/51/250

Quick Summary

The QA/8080/51/250 guide block delivers precise pneumatic actuation for automation and linear positioning in compact machinery. Engineers often struggle with achieving consistent stroke and alignment under load, while avoiding excessive wear and costly downtime. In regulated environments, CE compliance, IP protection levels, and SIL safety considerations shape supplier selection for motion control. The QA/8080/51/250 combines an 80 mm bore with a 250 mm stroke and a durable plain bearing guide block, delivering reliable performance and lower maintenance for automation & control systems. This helps procurement teams reduce refitting time, standardize parts, and simplify spare parts inventories across multiple lines. It also supports CAD-driven integration to accelerate engineering workflows.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

The QA/8080/51/250 uses an 80 mm bore and a 250 mm stroke to deliver substantial linear displacement within a compact footprint. This combination enables longer travel without extending mounting envelopes, reducing the need for additional actuators and simplifying machine layout in automation projects. The plain bearing style in the guide block minimizes friction and wear, translating to higher repeatability and lower maintenance costs over the lifecycle. In high-cycle applications such as pick-and-place and gaging routines, the design supports consistent performance under continuous operation. Compatibility with standard Norgren mounting patterns and simple alignment reduces commissioning time and risk of misalignment. Engineers can leverage existing fixture templates and spare parts to accelerate installation, ensuring reliable retention and precise alignment across multiple stations. CAD downloads and a dedicated installation guide streamline digital integration and on-site setup for automated lines. Access to model files helps simulate motion profiles before hardware is installed, reducing misconfiguration and rework. Reliable actuation with predictable stroke contributes to higher uptime and lower total cost of ownership in manufacturing lines. The combination of robustness and well-documented installation resources supports compliant, maintenance-friendly designs that meet industry uptime targets. As part of automation & control systems, this Norgren solution aligns with industry best practices for modular, scalable pneumatics. Designed to integrate alongside other IMI Norgren products, it simplifies procurement and standardizes performance across assemblies. Wear characteristics of the plain bearing guide block support longer service intervals and predictable performance under high-cycle operation. Manufacturers can rely on consistent motion during temperature variations and load changes, reducing rework and spare part consumption. Operationally, the unit pairs well with existing air preparation and filtration in standard plant air systems. For procurement teams, global availability of CAD assets and installation documentation accelerates design reviews and sourcing decisions.

Get a Quick Quote for a Norgren QA/8080/51/250

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/51/250?

Enquire Now

FAQs

Before integrating the QA/8080/51/250, confirm mounting compatibility with existing Norgren fixtures, verify bore and Stroke fit within your machine envelope, and ensure access to CAD models and the installation guide. Plan for proper air supply conditioning and basic alignment checks to minimize commissioning time and ensure repeatable motion from day one.

Key specifications include an 80 mm bore and a 250 mm stroke, along with the plain bearing guide block design that reduces friction and wear. For accurate force and speed characteristics, consult the installation guide and CAD resources, and determine operating pressure based on your system’s air supply and tooling.

Yes, the 80 mm bore and 250 mm stroke provide sufficient travel for many packaging tasks while maintaining a compact footprint. Its plain bearing guide block supports repeatable positioning, making it well-suited for medium-speed pick-and-place, machine tending, and similar automation routines when paired with proper guard, ducting, and air preparation.

Certification availability can depend on configuration and regional requirements. Confirm with the supplier whether CE marking, IP ratings, or SIL compliance are applicable to your application and ensure the specific order includes the required certifications and documentation.

The plain bearing guide block design aims for lower wear and longer service life, reducing maintenance frequency and downtime. Combined with downloadable CAD assets and installation guides, you can shorten commissioning time, improve uptime, and simplify spare parts management, contributing to a favorable total cost of ownership.