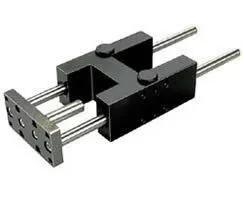

Norgren QA/8080/51/320 Guide Block - 80 mm Bore

Part Number: QA/8080/51/320

Quick Summary

QA/8080/51/320 guide block is a precise pneumatic actuator that delivers reliable linear motion for automation and assembly lines. It helps engineers achieve consistent stroke and alignment in constrained spaces, reducing setup time and repeatability issues. This cylinder family commonly meets CE requirements and offers robust environmental protection options; tracking with IP-rated variants and SIL-capable configurations enhances safety and compliance across production environments. By combining a plain bearing guide with a generous 80 mm bore and 320 mm stroke, it supports high-load tasks while minimizing maintenance. The model integrates smoothly with CAD workflows and installation guides, enabling faster deployment and easier OEM integration. In short, it balances performance, reliability, and total-cost-of-ownership for automated manufacturers.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

Feature: 80 mm bore with 320 mm stroke provides substantial actuation power and reach for compact layouts. Business impact: increased payload handling and longer stroke per cycle reduce the number of actuators needed on a line, cutting capital cost and space requirements. Application: suitable for pick-and-place fixtures, clamping stations, and transfer operations in automation and control systems. The combination supports consistent cycle timing even in dynamic environments, improving throughput without sacrificing accuracy. Feature: Guide block with plain bearing design minimizes sliding resistance and startup friction. Business impact: smoother motion, reduced wear, and lower maintenance costs over the cylinder's life. Application: high-frequency cycling on assembly lines and testing rigs where repeatability matters. Users benefit from quieter operation, longer service intervals, and fewer spare-parts needs, all contributing to lower total cost of ownership. Feature: Norgren engineering and CAD/installation resources streamline deployment. Business impact: faster commissioning, fewer integration errors, and better design-for-maintenance outcomes. Application: OEMs integrating actuators into automated machines benefit from downloadable CAD models and installation guides, which speed up drawings, bill-of-materials accuracy, and on-site assembly. Feature: Broad compatibility with automation ecosystems and safety considerations. Business impact: easier control integration, potential for SIL-rated configurations and CE-compliant usage in regulated environments, and improved risk management. Application: packaging lines, testing facilities, and process automation where predictable motion and robust construction matter.

Get a Quick Quote for a Norgren QA/8080/51/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/51/320?

Enquire Now

FAQs

QA/8080/51/320 is designed to align with standard Norgren mounting interfaces and uses common pneumatic connections. It provides downloadable CAD models and a dedicated Installation Guide to speed integration. Before mounting, confirm the 80 mm bore and 320 mm stroke match your fixture, verify mounting pattern compatibility, and use the CAD/BOM references to ensure correct fasteners and fittings.

Key specifications include an 80 mm cylinder diameter and a 320 mm stroke, with a plain bearing guide style that minimizes friction. The IMI Norgren branding signals a proven pedigree suitable for high-cycle automation scenarios. These metrics influence cycle speed, load capability, and positioning accuracy on test rigs, assembly lines, and packaging equipment.

Yes. The 80 mm bore and 320 mm stroke deliver substantial actuation travel in compact footprints, ideal for pick-and-place fixtures and transfer modules. The plain bearing guide supports repeatable motion with low maintenance, while CAD resources and installation guides speed commissioning. In packaging lines and test rigs, this model helps maintain cycle consistency under varying loads.

Certification details are not listed in the data sheet, but industrial cylinders commonly pursue CE compliance, IP-rated protection, and SIL-capable configurations for safety-critical tasks. Always verify via the Installation Guide and CAD downloads for your region, and consult Norgren's support channels to confirm current certifications for your specific configuration. You can request official certification documents from Norgren to validate compliance in regulated environments.

Expect reduced downtime thanks to a plain bearing design that minimizes friction and wear, extending service intervals and lowering spare-parts requirements. Integration with CAD resources shortens commissioning time, reducing labor costs on start-ups. Over a typical automation line, this translates to improved uptime, predictable motion, and a favorable total-cost-of-ownership when compared with legacy cylinders.