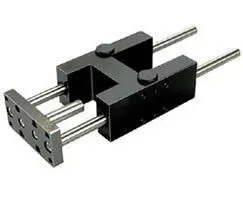

Norgren QA/8080/51/50 Pneumatic Cylinder - 80 mm Bore

Part Number: QA/8080/51/50

Quick Summary

The QA/8080/51/50 from Norgren is a precision pneumatic cylinder for linear actuation in automated manufacturing equipment. Operators struggle with alignment drift, wear, and downtime; this unit’s plain bearing design and robust 80 mm bore reduce sticking and maintenance. Designed to meet common industry standards, it aligns with CE conformity for European machinery, is compatible with IP‑rated environments, and supports SIL‑based safety architectures. Engineered for repeatable actuation under varying loads, it delivers stable cycle times and predictable performance across multiple applications. Easy mounting and installation, with downloadable CAD data and the official Installation Guide, translate to faster commissioning and lower total cost of ownership for OEMs and maintenance teams.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

80 mm bore with a 50 mm stroke provides robust actuation within a compact footprint, enabling stable velocity profiles and reliable load handling for mid-weight tasks. This geometry reduces peak stresses and wear on seals and guides, supporting longer service life and fewer unplanned outages in pick-and-place, clamping, and linear positioning applications. The plain bearing guide block design minimizes friction, delivering smoother operation across thousands of cycles and lowering lubrication requirements. That translates to higher equipment uptime and reduced maintenance costs in continuous production environments. Compatibility with standard mounting interfaces and Norgren actuator families simplifies retrofits and new installations, speeding commissioning and reducing engineering risk. CAD data and the Installation Guide are readily available, helping engineers verify hole patterns, clearances, and alignment before field assembly. The combination of a robust bore/stroke, durable bearing system, and clear documentation underpins lower total cost of ownership and predictable performance in automation and control system integrations.

Get a Quick Quote for a Norgren QA/8080/51/50

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/51/50?

Enquire Now

FAQs

QA/8080/51/50 uses standard mounting interfaces common to Norgren pneumatic cylinders, simplifying integration with existing frames and tooling. For detailed spacing and hole locations, consult the CAD model referenced in Downloads and the Installation Guide PDF. These resources help ensure correct alignment with the 80 mm bore and 50 mm stroke, reducing setup time and risk of misalignment during commissioning.

An 80 mm bore provides ample clamping and pushing force for mid-range applications, while the 50 mm stroke supports precise end-of-stroke positioning. Together they enable repeatable cycle times and predictable actuation across vibration and load variations. This makes it suitable for pick-and-place, packaging, and fixture operations.

While explicit certifications are not listed here, the unit is designed to align with CE conformity for European machinery and supports operation in environments typical of IP-rated applications. For safety systems, it can be integrated with SIL-based control schemes. Always verify current certifications in your procurement documentation and with the supplier.

Yes. CAD data is available via the CAD download, and the Installation Guide (PDF) is provided in the Downloads section. Access to these resources reduces design time and ensures correct installation, alignment, and mounting with the 80 mm bore type.

Plain bearing guidance offers smooth motion with less friction, typically reducing lubrication intervals and wear-related downtime. Regular inspection of seals and end caps is advised, and the availability of spare parts from Norgren helps minimize long-term maintenance costs. This approach supports higher uptime in continuous production lines.