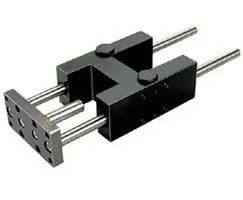

Norgren QA/8080/51/500 Guide Block - 80 mm Bore

Part Number: QA/8080/51/500

Quick Summary

Norgren QA/8080/51/500 guide block is a precision linear actuator designed for reliable positioning in automation and packaging lines. It features an 80 mm bore and a 500 mm stroke, with plain bearing guidance delivering smooth motion under high-cycle loads. Primary applications include pick-and-place stations, fixture alignment, and transfer tasks within automated assembly cells. Why it matters: reduced friction and wear extend service life, while the robust body supports lower maintenance costs in demanding environments. CAD models and the Installation Guide PDF are readily available to accelerate design reviews and commissioning, helping technicians confirm fit, clearance, and mounting compatibility before hardware arrives. Integrated with Norgren's QA family, this block promotes predictable runout, repeatability, and board-to-line consistency across modern control systems.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

Feature: 80 mm bore and 500 mm stroke provide a broad motion envelope that accommodates varied payloads and longer travel in compact automation cells. Business impact: expands application versatility without multiple SKUs, reducing part-number proliferation and engineering time. Application: ideal for high-cycle pick-and-place and transfer tasks in packaging lines where repeatable motion is critical. Long-tail keywords: 80 mm bore cylinder, 500 mm stroke, motion envelope, high-cycle automation, packaging line equipment. Feature: Plain bearing guide block design minimizes friction and wear, delivering smoother operation and longer service life. Business impact: lowers maintenance costs and minimizes downtime due to wear-related performance drift. Application: suited for repetitive, high-speed positioning in assembly cells and fixture-based automation. Long-tail keywords: plain bearing guidance, reliable linear motion, wear reduction, high-cycle life, assembly automation. Feature: Compact body design and standard mounting interfaces support quick installation and easy integration into tight spaces. Business impact: accelerates commissioning, reduces control cabinet footprint, and improves machine uptime. Application: retrofit projects and new lines in tight install environments. Long-tail keywords: compact guide block, installation-friendly, quick mounting, tight spaces, retrofit automation. Feature: CAD data and installation documentation (CAD model downloads and Installation Guide PDF) streamline engineering workflows. Business impact: minimizes pre-build errors, shortens project timelines, and improves first-pass assembly quality. Application: system integrators and OEMs orchestrating multi-vendor automation stacks. Long-tail keywords: CAD download, Installation Guide PDF, engineering efficiency, OEM integration, system integrator support. Feature: Brand alignment with the Norgren QA family ensures consistent performance and spare parts availability. Business impact: supports longer lifecycle planning and easier component replacement. Application: upgrades to legacy lines and standardization across production cells. Long-tail keywords: QA family compatibility, spare parts availability, lifecycle planning, standardized automation, Norgren reliability.

Get a Quick Quote for a Norgren QA/8080/51/500

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/51/500?

Enquire Now

FAQs

The QA/8080/51/500 uses the typical Norgren QA guide block mounting interface. Consult the Installation Guide PDF for recommended bolt patterns, alignment tolerances, and mounting sequence. Ensure the 80 mm bore aligns with the guide rail and that end stops are set to prevent over-stroke. Use standard fasteners suitable for your frame material and environment.

The unit features an 80 mm bore and a 500 mm stroke. This combination provides a wide travel range within a compact 80 mm bore package, enabling versatile placement along automated transfer paths and fixtures while maintaining precise repeatability across cycles.

Yes. Download CAD models and the Installation Guide PDF are supplied to support pre-install checks, fit verification, and assembly planning. Access these resources from the productDownloads section or the Norgren support portal to speed up design review and commissioning.

Verify CE compliance and consult the datasheet for IP ratings and SIL options where applicable. Certification requirements vary by configuration and region, so cross-check the specific model variant with the official datasheet and your project spec to ensure regulatory alignment.

By delivering smooth, low-wear motion with a long service life, the block reduces maintenance downtime and replacement frequency. The availability of CAD assets and installation guides accelerates commissioning, while compatibility with the QA family supports standardized spares and faster upgrades across multiple lines.