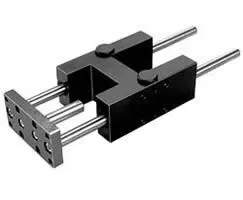

Norgren QA/8080/61/100 Pneumatic Cylinder - 80 mm Bore

Part Number: QA/8080/61/100

Quick Summary

QA/8080/61/100 pneumatic cylinder delivers precise linear motion for automated assembly lines and machining processes. Engineers often struggle with misalignment, frictive wear, and inconsistent stroke length from conventional guides—this design minimizes those issues and boosts repeatability. Typical certifications to verify for automation components include CE marking, IP protection ratings, and ISO 6431 compatibility. Check the datasheet to confirm exact certifications for your region. This model aligns with Norgren's precision standards while offering compatibility with standard mounting interfaces and supply connections, enabling faster deployment and lower life-cycle costs for modern production environments.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

Feature: 80 mm bore with 100 mm stroke and roller bearing style guide block. Business Impact: Delivers controlled, repeatable actuation with reduced friction, extending cycle life and lowering maintenance costs. Application: Ideal for high-speed indexing, pick-and-place, and precision clamping in compact automation cells. By using a robust guide system, you achieve tighter part positioning and consistent stroke across cycles, translating to higher first-pass yields. Long-tail keywords: 80 mm bore pneumatic cylinder, roller bearing guide, precise actuation, high-cycle automation, compact actuator compatibility.Feature: Compatibility with standard mounting interfaces and CAD resources. Business Impact: Accelerates design-in, minimizes rework, and speeds installation. Application: Engineering teams can import CAD models directly into their assembly processes and verify fit before fabrication. This reduces project timelines and helps maintain BOM accuracy. Long-tail keywords: ISO mounting patterns, CAD downloads, installation guide, Norgren compatibility, assembly planning.Feature: Durable construction and low-maintenance operation. Business Impact: Lower downtime through smoother operation and fewer wear-induced failures. Application: Suitable for harsh production environments, where debris and vibration stress the guide system. Long-tail keywords: roller-guided cylinders, low-friction actuation, maintenance-friendly design, industrial automation reliability.Feature: Compact footprint with reliable stroke control. Business Impact: Enables retrofits and fits into tight spaces without compromising performance. Application: Upgrades to existing lines in packaging, automotive turnkey cells, and machine-tending stations. Long-tail keywords: compact pneumatic cylinder, space-saving actuator, retrofit-ready cylinder, high-precision alignment.

Get a Quick Quote for a Norgren QA/8080/61/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/61/100?

Enquire Now

FAQs

QA/8080/61/100 is designed for common ISO mounting patterns used on pneumatic cylinders. When preparing installation, verify bore alignment, mounting spacers, and connection fittings to ensure zero-endplay. The availability of CAD models and an Installation Guide simplifies pre-assembly checks, reduces rework, and helps you achieve repeatable, vibration-free operation on automated lines.

In high-cycle environments, the 80 mm bore and 100 mm stroke provide consistent force delivery and stroke precision across thousands of cycles. The roller bearing guide minimizes friction and stick-slip, boosting life expectancy and reducing maintenance intervals. Expect improved repeatability in indexing, clamp positioning, and part transfer, contributing to higher overall equipment effectiveness (OEE).

Yes, the QA/8080/61/100 suits packaging and automotive assembly lines where precise, repeatable motion is essential in pick-and-place, clamping, and transfer tasks. Its compact footprint and compatibility with standard interfaces make it easy to retrofit into existing cells. For best results, pair with appropriate sensors and a matched controller to optimize cycle times and positioning accuracy.

Certifications for automation cylinders typically include CE marking and IP protection ratings, with ISO 6431 compatibility widely referenced for dimensional and mounting standards. To confirm exact certifications for your region and application, consult the datasheet and installation guide linked in the product downloads. If in doubt, contact your Norgren distributor for Documentation Pack validation.

Upgrading to QA/8080/61/100 can reduce downtime and maintenance costs due to lower wear from roller guidance and smoother movement. The improved repeatability minimizes scrap from misalignment, while faster design-in lowers engineering hours. Over time, you should see lower total cost of ownership (TCO) and steadier production output, particularly in high-cycle, high-precision tasks.