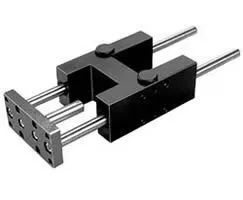

Norgren QA/8080/61/160 Guide Block - 80 mm Bore

Part Number: QA/8080/61/160

Quick Summary

The Norgren QA/8080/61/160 guide block provides precise linear guidance for automation equipment in factory lines. Engineers often battle wear-induced play and misalignment that cause downtime and costly maintenance. Designed to support CE compliance and industry safety practices, with reliable performance in standard industrial environments. In practice, it plugs into existing Norgren or compatible mounting patterns, streamlining installation and reducing setup mistakes. This compact model, with an 80 mm bore and 160 mm stroke, is ideal for automation applications like pick-and-place, packaging lines, and machine tending, delivering improved repeatability and lower maintenance. It ships with CAD and installation resources to accelerate design-in and commissioning. That combination helps maintenance teams justify ROI with predictable performance.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The QA/8080/61/160 guide block uses an 80 mm bore and 160 mm stroke to deliver tight positional accuracy under load, reducing end-of-stroke drift and repeatability errors. This enables tighter assembly tolerances and fewer reworks in automated lines such as conveyors and material handling. Feature → Business Impact → Application: Roller bearing style minimizes friction and wear, extending service life and lowering lubrication needs, which reduces downtime and spare-parts costs in high-cycle operations like packaging lines. Feature → Business Impact → Application: Compatibility with standard Norgren mounting patterns speeds installation and retrofit projects, cutting engineering and commissioning time for OEMs and integrators. Feature → Business Impact → Application: CAD data and installation guides accelerate design-in and accurate assembly, minimizing field errors during commissioning. Feature → Business Impact → Application: CE-aligned design supports regulatory compliance in European deployments, delivering reliable performance in general industrial environments.

Get a Quick Quote for a Norgren QA/8080/61/160

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/61/160?

Enquire Now

FAQs

Yes. The QA/8080/61/160 uses standard Norgren mounting patterns and is designed for straightforward retrofit or integration with existing blocks. CAD resources are available to ensure accurate dimensioning, simplifying design decisions and reducing installation lead times on automation projects.

The model features an 80 mm bore and a 160 mm stroke with a roller bearing style for low friction. This combination minimizes lateral play and wear, boosting repeatability and reducing drift during high-cycle operations such as packaging and pick-and-place, thereby lowering rework and maintenance costs.

Yes. Its compact footprint, robust roller bearing guidance, and precise 80 mm bore with 160 mm stroke make it well-suited for packaging conveyors, box handling, and material flow applications where accurate linear motion and reliability are critical for throughput and uptime.

While specific certifications aren’t listed in the data, Norgren products commonly align with CE compliance and standard industrial safety practices. For EU deployments, ensure your system integrates with CE-compliant components and follows local electrical and mechanical safety requirements.

The product pack includes CAD data and an Installation Guide (PDF), enabling precise engineering, faster design-in, and more predictable commissioning. These resources help reduce field errors, shorten downtime during changes, and justify ROI with improved consistency and reduced maintenance intervals.