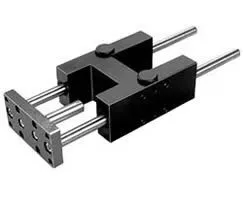

Norgren QA/8080/61/200 Guide Block Roller - 80 mm Bore

Part Number: QA/8080/61/200

Quick Summary

Norgren QA/8080/61/200 Guide Block Roller is a compact linear actuator designed for precise motion control in automated assembly lines. Engineers often face misalignment and wear in long-stroke actuators, leading to downtime and higher maintenance costs. Typical configurations in this line support CE compliance, IP ratings, and SIL-ready safety integration, ensuring reliable performance in challenging industrial environments. This combination of compact form, robust roller guidance, and readily available CAD resources accelerates integration, reduces part-count, and lowers total cost of ownership for OEMs and maintenance teams.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

Feature: 80 mm bore with a 200 mm stroke using a roller bearing style 61 guide block. Benefit: Delivers smooth, low-friction linear motion with high repeatability, reducing wear and maintenance while increasing cycle consistency in pick-and-place and clamp tasks. Application: Ideal for packaging lines and automated assembly where tight tolerances and long life matter. Feature: Robust roller guidance enhances load distribution and rigidity. Benefit: Improves precision over extended runs and enables faster cycle times without sacrificing accuracy. Application: Suitable for high-speed conveyor interfaces and transfer stations in manufacturing environments. Feature: Compact form factor with standardized mounting options. Benefit: Simplifies integration with existing frames and ISO patterns, shortening installation times and reducing engineering effort. Application: Applicable across retrofit projects and OEM line expansions. Feature: Availability of CAD assets and installation guides. Benefit: Speeds up development, validation, and commissioning, lowering project risk. Application: Commonly used by engineers during concept reviews and FAT testing. Feature: Clear data resources and documented compatibility. Benefit: Streamlines procurement and enables proactive maintenance planning, lowering total cost of ownership. Application: Useful for maintenance teams scheduling preventive servicing and part replacements.

Get a Quick Quote for a Norgren QA/8080/61/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/61/200?

Enquire Now

FAQs

Yes. The QA/8080/61/200 is designed to fit common ISO mounting patterns used across automation frames, enabling straightforward swap-ins and retrofits. When planning installation, verify bore and stroke to match your fixture, consult the Installation Guide PDF for exact hole spacing and fastener sizes, and ensure proper alignment to minimize side loads that could affect life and accuracy.

The actuator features an 80 mm cylinder bore and a 200 mm stroke, providing a balance between piston area and travel length. The bore determines pushing force at a given pressure, while the stroke defines travel distance. Performance in terms of speed and force will depend on supply pressure and load; this class of actuator prioritizes repeatability and smooth motion for reliable cycle times.

This guide block roller excels in automated assembly, pick-and-place, and clamping tasks where precise, repeatable motion is critical. The roller bearing guidance reduces friction, increasing life and stability on packaging lines, transfer positions, and test rigs. Its compact form also suits retrofits and limited-access installations where space is at a premium.

Industry-standard certifications commonly associated with this product family include CE compliance for safety, IP-rated housings for environmental protection, and SIL-ready configurations for safety integrity in control systems. Always confirm the exact model variant with your supplier and ensure your application meets local machine safety and environmental requirements before deployment.

Expect lower maintenance frequency thanks to roller-guided, low-friction motion and robust construction. CAD resources and installation guides shorten integration and commissioning time, accelerating time-to-value. When planning ROI, factor in reduced downtime, longer service life, and faster replacement part availability, all supported by clear documentation and compatibility with standard mounting patterns.