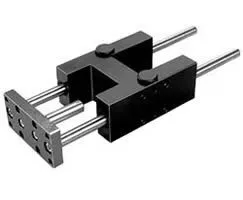

Norgren QA/8080/61/250 Guide Block Cylinder - 80 mm Bore 250 mm Stroke

Part Number: QA/8080/61/250

Quick Summary

QA/8080/61/250 Guide Block Cylinder provides precise linear motion for automated assembly lines. Engineers often face misalignment, stiction, and wear in long-stroke cylinders that disrupt production and raise maintenance costs. Designed to meet common industry standards such as CE and IP ratings where applicable, and compatible with SIL-rated control architectures when required. This unit integrates with standard mounting blocks and CAD resources to speed up commissioning, while delivering reliable lifecycle performance for high-availability automation. With an 80 mm bore and a 250 mm stroke, it enables predictable throughput and reduced total cost of ownership in modern manufacturing environments.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

Feature: 80 mm bore and 250 mm stroke deliver precise, repeatable linear motion in a compact form. Business Impact: The combination of a guide block roller bearing and robust construction minimizes parasitic motion, reduces stiction, and extends cycle life, translating into lower maintenance costs and more consistent throughput. Application: Ideal for automated assembly lines, fixture clamping, and transfer operations where predictable travel and repeatability matter. Feature: Guide block roller bearing style provides high rigidity and load- carrying capability. Business Impact: By distributing side loads across a rolling contact path, it maintains alignment at higher speeds and under modest misalignment, which reduces wear and downtime. Application: Suitable for high-speed pick-and-place, inspection fixtures, and machine-tending stations in modern manufacturing environments. Feature: Compatibility with standard mounting patterns and available CAD resources. Business Impact: Accelerates integration and retrofit, reduces engineering time and risk. Application: Works with Norgren mounting blocks and end fittings to fit existing automation frameworks. Feature: CAD downloads and Installation Guide PDF enable faster design-in and on-site setup. Business Impact: Minimizes design mistakes and lubrication planning time, improving overall project discipline. Application: Used during design reviews and on-site commissioning across automation projects. Feature: Durable design with robust materials and a long service life. Business Impact: Delivers predictable lifecycle performance, lowering total cost of ownership in high-cycle environments. Application: Suitable for broad industrial automation tasks requiring reliable pneumatic actuation.

Get a Quick Quote for a Norgren QA/8080/61/250

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/61/250?

Enquire Now

FAQs

The QA/8080/61/250 uses IMI Norgren’s guide block roller bearing style with an 80 mm bore and 250 mm stroke. It supports standard mounting patterns and end fittings within Norgren’s ecosystem, reducing retrofit work. For design validation, download the CAD model and Installation Guide to confirm clearances, tightening torques, and alignment tolerances before integration.

Begin by verifying supply pressures and mounting locations. Secure the cylinder with compatible brackets and end mounts, following the CAD-based hole patterns. Align to minimize side load, then connect the actuating lines. Use the Installation Guide for lubrication intervals, travel stop settings, and commissioning checks to ensure repeatable performance.

Ideal for automated assembly lines, fixture clamping, transfer operations, and machine tending where precise, repeatable strokes are required. The roller bearing guide supports higher speeds with reduced wear, making it well-suited for high-cycle automation tasks and reliable position control in challenging environments.

The QA/8080/61/250 is designed to support common regulatory requirements in automation projects. Where applicable, it can be integrated with CE-marked equipment and IP-rated environments, and it can be used with SIL-rated control architectures when required. Always verify your specific installation meets your site safety and regulatory standards using the provided installation resources.

Thanks to the roller bearing guide, wear is distributed more evenly, delivering longer service life in high-cycle operation. Regular inspection and lubrication per the guide, along with CAD-driven spare parts planning, help optimize uptime and reduce unexpected downtime, delivering a lower total cost of ownership over the product lifecycle.