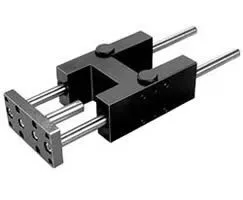

Norgren QA/8080/61/320 Guide Block Roller Bearing - 80mm Bore

Part Number: QA/8080/61/320

Quick Summary

Norgren QA/8080/61/320 is a guide block roller bearing style actuator delivering precise linear motion for compact automation stages. In tight automation lines, misalignment and stiction can derail cycles, increasing downtime and scrap. When selecting actuators, look for CE conformity and robust mounting interfaces, plus industry-standard interfaces for quick swaps; many Norgren products align with CE safety standards, IP ratings where applicable, and SIL-ready configurations for safety-critical use. This model integrates with CAD data, installation guides, and compatible control valves to shorten commissioning and reduce lifecycle costs, enabling faster ROI for OEMs and maintenance teams alike. For engineers, this means reliable motion in critical packaging, assembly, and transfer tasks with predictable performance across cycles.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The QA/8080/61/320 uses a guide block roller bearing style mechanism that delivers smooth, low-friction travel, reducing wear and energy consumption in high-cycle applications. This translates to longer service life and lower maintenance costs on material-handling lines and pick-and-place stations. Application-wise, it supports compact automation layouts where precision positioning is essential and alignment tolerance is tight, such as assembly arms or transfer units. Feature → Business Impact → Application: An 80 mm bore with a 320 mm stroke provides substantial travel within a compact envelope, enabling longer strokes without oversized housings. This reduces the number of actuators required per line and simplifies machine footprint planning. Feature → Business Impact → Application: Standard mounting interfaces and compatibility with Norgren control valves and manifolds streamline integration, cutting commissioning time and safeguarding against compatibility gaps in multi-vendor systems. Feature → Business Impact → Application: Availability of CAD data and an Installation Guide enables engineering teams to validate fitment virtually before build, reducing rework and ensuring correct alignment from day one. Feature → Business Impact → Application: The roller-bearing guidance minimizes misalignment under high-cycle loads, improving repeatability and process control in packaging, labeling, and precision assembly tasks. Feature → Business Impact → Application: The actuator is designed for straightforward maintenance, with accessible serviceable components and compatible spare parts, lowering total cost of ownership. Feature → Business Impact → Application: Its robust design supports scalable automation strategies, allowing OEMs to expand lines or reconfigure layouts with minimal redesigns, supporting future productivity gains and reduced downtime.

Get a Quick Quote for a Norgren QA/8080/61/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/61/320?

Enquire Now

FAQs

QA/8080/61/320 uses standard mounting interfaces common to Norgren actuators, and its 80 mm bore with 320 mm stroke fits typical automation layouts. CAD data and the installation guide streamline mounting calculations, alignment checks, and accessory selection such as end fittings and control valves.

Ensure proper alignment of the guide rails to prevent side loads, use clean compressed air, and apply recommended lubrication intervals. Install with appropriate mounting hardware to minimize backlash and verify that the stroke direction matches the intended travel path to reduce wear.

Yes. The guide block roller bearing design reduces friction and wear, supporting high-cycle operation. Pairing with compatible Norgren valves and a robust pneumatic system helps maintain repeatability and reduces downtime due to component wear.

Verify CE conformity for safety and electrical compatibility, and review any application-specific requirements such as SIL readiness or IP ratings. Consult the supplier for current certification documentation and compatibility with your safety and environment standards.

Investing in QA/8080/61/320 can reduce downtime through improved repeatability and longer service life, lower energy consumption due to efficient motion, and faster commissioning thanks to CAD data and installation guidance. These factors combine to shorten payback on line upgrades and improve overall equipment effectiveness.