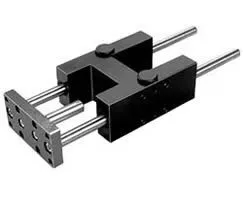

Norgren QA/8080/61/400 Guide block roller bearing - 80 mm bore

Part Number: QA/8080/61/50

Quick Summary

Norgren QA/8080/61/400 is a guide block roller bearing cylinder for precise linear motion in automation systems. Engineers often struggle with misalignment, wear, and frequent maintenance; this design reduces play and extends service life, delivering consistent cycle accuracy. Designed for CE-compliant environments and rugged industrial use, it supports reliable performance in SIL-rated control schemes and with safety components in IP-rated installations. By leveraging standard mounting interfaces and readily available CAD resources, teams can shorten integration time, minimize downtime, and improve total cost of ownership across manufacturing lines.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

Feature: 80 mm bore and 400 mm stroke provide ample travel with robust force delivery. Business Impact: Enables longer reach without sacrificing precision, reducing cycle times and operator intervention. Application: Ideal for automated assembly, packaging lines, and material handling where consistent stroke is essential. Feature: Roller bearing guide minimizes side load effects and wear. Business Impact: Extends service life, lowers maintenance frequency, and improves repeatability, especially in high-cycle environments. Application: Conveyor transfers and pick-and-place fixtures that demand tight alignment. Feature: CAD downloads andInstallation Guide (PDF) simplify design-in and commissioning. Business Impact: Accelerates engineering workflows, reduces design errors, and improves spares planning. Application: System integration on new lines or retrofit projects. Feature: Standard mounting compatibility with Norgren components. Business Impact: Reduces part count, simplifies replacement, and enables rapid field service. Application: Retrofit of legacy systems or expansion of existing automation cells. Feature: Rugged construction suits demanding industrial environments. Business Impact: Improves uptime and reliability in manufacturing floors, reducing unplanned downtime. Application: Heavy-use automation, robotics-assisted tasks, and packaging operations.

Get a Quick Quote for a Norgren QA/8080/61/50

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/61/50?

Enquire Now

FAQs

QA/8080/61/400 uses standard Norgren guide-block mounting interfaces, with end-plate compatibility and common inline configurations. This simplifies retrofit and new-build installations, allowing straightforward alignment with existing frames and tie-rod mounts. For precise fitment, consult the Installation Guide and CAD resources to select the correct orientation, mounting bolts, and brackets for your machine design.

The unit features an 80 mm bore and a 400 mm stroke, delivering robust travel with consistent actuation force. The roller bearing guide minimizes side loads and wear for high-cycle reliability. Compatibility with standard Norgren components ensures predictable force curves, repeatability, and straightforward maintenance in automated lines and tooling applications.

This guide block roller bearing cylinder excels in packaging, assembly, automation tooling, and material-handling contexts where precise linear motion and repeatable positioning are critical. It is well-suited for pick-and-place cells, fixture actuation, and conveyor transfers where consistent stroke and reliable guidance reduce downtime and improve throughput.

The QA/8080/61/400 is designed for CE-compliant environments and aligns with industry expectations for robust automation components. For system-level safety, compatibility with SIL-rated control schemes and IP-rated environments should be ensured by incorporating appropriate safety devices and protective enclosures. Always verify project-specific certifications during integration with your compliance team.

The roller-bearing guide reduces wear and misalignment, extending service intervals and reducing unplanned downtime. Availability of CAD files and installation guides accelerates commissioning, lowers design risk, and streamlines spare-parts planning. Over the life of a production line, these factors translate to higher uptime, lower maintenance costs, and quicker return on investment.