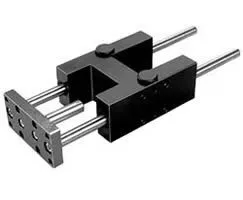

Norgren QA/8080/61/500 Guide Block Roller - 80 mm bore, 500 mm stroke

Part Number: QA/8080/61/500

Quick Summary

QA/8080/61/500 guide block roller actuators deliver precise linear motion for automated assembly lines. When integrating into compact automation cells, engineers often wrestle with stroke limits and misalignment that disrupt cycle times. This product aligns with CE compliance and offers rugged performance suitable for common control architectures; for harsher environments, verify IP ratings and any SIL-rated options with the supplier. By combining robust design with easy mounting and broad compatibility, it helps reduce design time, streamline supplier interactions, and support scalable line upgrades.

Product Information

Cylinder diameter

80 mm

Brand

IMI Norgren

Feature: 80 mm cylinder diameter and 500 mm stroke provide extended travel within tight footprints. Business Impact: Enables longer reach and fewer retractions, boosting cycle efficiency and reducing machine footprint. Application: Packaging lines and pick-and-place fixtures where space is at a premium. Feature: Guide block roller bearing style delivers low-friction, smooth motion and reduced wear. Business Impact: Lower energy consumption, longer service intervals, and predictable performance across high-cycle applications. Application: High-speed automation cells with repetitive travel. Feature: Brand reliability and standardization with Norgren lineage enhances compatibility with existing control systems. Business Impact: Consistent performance across lines reduces integration risk and simplifies maintenance planning. Application: Multi-robot workstations and automation platforms requiring uniform component behavior. Feature: Availability of CAD models and Installation Guide facilitates rapid integration. Business Impact: Shortens design time, improves accuracy during installation, and minimizes commissioning delays. Application: Engineering teams importing components into CAD environments for fast platform validation. Feature: Compatible mounting patterns and standard fittings streamline retrofits and upgrades. Business Impact: Easier retrofits in legacy equipment, reduced tooling changes, and faster time-to-value. Application: Retrofit projects in manufacturing lines undergoing capacity or speed improvements.

Get a Quick Quote for a Norgren QA/8080/61/500

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8080/61/500?

Enquire Now

FAQs

QA/8080/61/500 uses industry-standard mounting patterns compatible with IMI Norgren actuators. To confirm compatibility with your frame, consult the CAD download and Installation Guide linked in the product downloads, verify bore alignment, mounting hole spacing, and any required accessory brackets before ordering.

Key specifications include an 80 mm cylinder bore and a 500 mm stroke, paired with a guide block roller bearing arrangement for low-friction motion. These features enable smooth, repeatable travel in compact spaces, suitable for high-cycle automated lines and fixture applications.

Yes, the roller-bearing design supports high-cycle operation with reduced wear. Regular maintenance should focus on lubrication per the Installation Guide and periodic inspection of seals and fittings to maintain performance and prevent drag in long-running cycles.

CE compliance is commonly required for European operations. Depending on your environment, verify IP ratings and any SIL-rated options with the supplier to ensure suitability for your safety and reliability requirements in your specific application.

The low-friction roller guidance and standardized mounting reduce wear and streamline installation, which translates to longer service intervals, faster commissioning, and lower maintenance costs. This can lead to reduced downtime and faster time-to-value during line upgrades or reconfigurations.