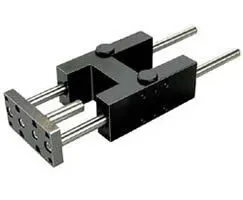

Norgren QA/8100/51/100 Guide Block - 100 mm Bore

Part Number: QA/8100/51/100

Quick Summary

Norgren QA/8100/51/100 guide block is designed to provide precise linear guidance for automated assemblies. Engineers often struggle with misalignment, wear, and downtime in high-cycle pneumatic systems. Typical regional requirements include CE marking for Europe, IP-rated environmental protection, and SIL considerations depending on configuration. These factors drive installation confidence, reduce unplanned maintenance, and support efficient procurement. Leveraging the 100 mm bore, 100 mm stroke format and readily available CAD data, this block accelerates deployment while aligning with standard mounting patterns for broader compatibility.

Product Information

Cylinder diameter

100 mm

Brand

IMI Norgren

Feature: 100 mm bore and 100 mm stroke in a compact guide block. Business impact: enables tight, predictable motion in limited spaces, reducing assembly footprint and speeding up line layout. Application: packaging lines, machine tending, and conveyor systems that demand consistent alignment. Feature: Plain bearing style delivers low friction and predictable wear. Business impact: longer service life, lower lubrication needs, and quieter operation in high-cycle cycles. Application: high-volume pick-and-place and continuous-motion applications where maintenance intervals are critical. Feature: Compatibility with standard mounting patterns and CAD data. Business impact: faster engineering, easier retrofits, and reduced commissioning risk. Application: integration into existing automation cells and modular frames with minimal rework. Feature: Availability of CAD models and installation guides. Business impact: accelerates virtual prototyping, error-free installation, and reduced on-site debugging. Application: projects that require rapid deployment and validated mounting clearances. Feature: Certification readiness and regional compliance context. Business impact: verified regulatory alignment across regions, simplifying procurement and audit trails. Application: global manufacturing environments that must meet CE, IP, and SIL considerations depending on configuration.

Get a Quick Quote for a Norgren QA/8100/51/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8100/51/100?

Enquire Now

FAQs

The QA/8100/51/100 is designed for standard 100 mm bore installations with a compact footprint and compatible mounting patterns. It supports common alignment features and fasteners used in automation cells, enabling straightforward retrofits and predictable integration with existing pneumatic cylinders and guide rails.

The plain bearing design delivers low friction, reduced wear, and stable motion across thousands of cycles. This translates to lower lubrication needs, cooler operation, and extended service life, reducing maintenance interruptions in packaging lines, material handling, and high-speed conveying systems.

CAD models are available via the Part Community link provided by Norgren, and the Installation Guide PDF can be downloaded from Norgren’s repository. These resources help with accurate 3D placement, interference checks, and proper mounting clearances before build-out.

Check for CE marking for European installations and verify any region-specific IP ratings for environmental protection. SIL considerations depend on your safety-function configuration. Always confirm the exact certifications tied to your configuration in the installation guide and CAD package supplied with the product.

ROI is driven by reduced downtime, lower maintenance intervals, and improved line availability due to tighter tolerances and reliable motion. The CAD data and standardized mounting reduce commissioning time, while the durable plain bearing design lowers wear-related costs, delivering faster payback in high-volume packaging or assembly operations.