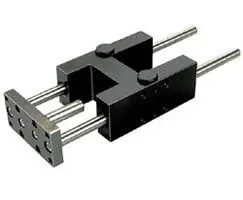

Norgren QA/8100/51/160 Guide block - 160 mm stroke

Part Number: QA/8100/51/160

Quick Summary

QA/8100/51/160 guide block delivers precise linear actuation for automation and control systems. When selecting cylinders, engineers waste time on mismatched bore or stroke, leading to downtime and rework. This design supports CE conformity and IP-rated protection, with SIL-ready performance for safety-critical lines. Designed for easy integration, the compact 100 mm bore and 160 mm stroke simplify layouts and spare parts management, while CAD files and installation guides streamline commissioning. In short, Norgren QA/8100/51/160 reduces downtime, improves repeatability, and lowers life-cycle costs for automation projects.

Product Information

Cylinder diameter

100 mm

Brand

IMI Norgren

Feature: The QA/8100/51/160 delivers a 100 mm bore and 160 mm stroke, offering robust actuation in a compact envelope. Business Impact: This combination increases push force and stroke travel without enlarging the machine footprint, enabling faster cycle times and better positioning accuracy on constrained lines. Application: Ideal for packaging, automated assembly, and process tooling where space is at a premium and repeatability matters. Feature: Guide block plain bearing style minimizes sliding friction and provides smooth, consistent motion across thousands of cycles. Business Impact: Lower wear translates to extended service life, reduced maintenance windows, and lower spare-parts consumption—crucial for high-uptime manufacturing. Application: Well suited for vertical or horizontal actuations in automation cells, regardless of mounting orientation. This design tolerates a wide range of ambient temperatures, ensuring reliable operation on factory floors. Feature: Rich design ecosystem includes CAD download and a dedicated Installation Guide PDF. Business Impact: Engineers can model and integrate the actuator earlier, reducing commissioning time and design errors. Application: Supports seamless integration with Norgren fittings and downstream control systems in conveyors, racking, and clamping modules. Having CAD compatibility reduces part variance in assemblies and improves vendor alignment across engineering teams. Feature: Compact footprint and flexible mounting compatibility simplify retrofits and new installs. Business Impact: Smaller machine footprints free up cabinet space, lower enclosure costs, and ease automation projects. Application: Fits into retrofit projects and new builds in packaging, tooling, and material handling where space is tight and spare parts logistics matter. Feature: Durability and sealing designed for industrial environments, with CE conformity and IP considerations. Business Impact: Robust protection reduces dirt ingress and wear, boosting uptime and total-cost-of-ownership. Application: Best applied on factory floors with dust, splash zones, and mixed-temperature operation; the design also supports easy field replacement for minimal production impact.

Get a Quick Quote for a Norgren QA/8100/51/160

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8100/51/160?

Enquire Now

FAQs

Yes. QA/8100/51/160 uses the established Norgren mounting geometry, ensuring straightforward fitment with existing frame plates and end fittings. Refer to the CAD download and Installation Guide PDF for exact hole patterns, fastener sizes, and torque recommendations to guarantee a clean retrofit or new installation.

The unit features a 100 mm bore and a 160 mm stroke, configured in a guide block plain bearing style for smooth, low-friction movement. Operating on standard pneumatic supply ranges, it is designed for precise, repeatable actuation in automation and control systems, with CAD compatibility to facilitate accurate modeling and integration.

Ideal for packaging lines, automated assembly, and machine-tool operations where space is constrained and cycle precision is critical. The 100 mm bore delivers adequate actuation force, while the 160 mm stroke supports longer travel. The device also suits material handling and clamping modules, enabling reliable, repeatable motion in demanding environments.

QA/8100/51/160 is designed with CE conformity in mind and offers IP-rated protection where applicable, supporting safe operation in typical industrial environments. For safety-critical lines, plan SIL-ready integration with your safety system and confirm site-specific IP and compliance requirements with your systems integrator.

The plain bearing design reduces wear, lowering maintenance frequency and spare-parts costs, while the CAD/download resources shorten design and commissioning timelines. Choosing QA/8100/51/160 can yield higher uptime, improved repeatability, and a faster time-to-production for automation projects, translating into tangible lifecycle cost savings.