Norgren QA/8100/51/200 Cyl. -100mm Bore,200mm Stroke

Part Number: QA/8100/51/200

Quick Summary

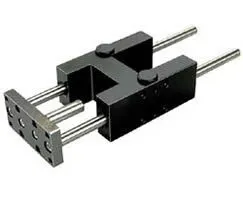

QA/8100/51/200 pneumatic cylinder is a precision actuator designed for automated assembly, pick-and-place, and packaging lines. Engineers often face misalignment, wear, and downtime in high-cycle environments, which degrade throughput and increase maintenance costs. In general, certifications such as CE marking, IP ratings, and SIL readiness are key considerations for compliant, safe automation solutions, and this model fits that context. The design supports scalable OEM integration with standard mounting interfaces and comprehensive documentation, helping firms reduce design time, simplify procurement, and lower total cost of ownership through easier maintenance and compatibility with Norgren accessories.

Product Information

Cylinder diameter

100 mm

Brand

IMI Norgren

The 100 mm bore and 200 mm stroke provide extended travel and robust loading capacity, reducing the number of cylinders needed on a line and simplifying control logic. This translates to fewer components, lower inventory, and a smaller footprint in packaging and assembly applications, leading to faster changeovers and improved line throughput. The guide block plain bearing style 51 delivers low friction, smooth operation, and longer service intervals, decreasing wear-related downtime on high-cycle indexing and repetitive-motion tasks. Compatibility with standard Norgren mounting interfaces enables quick installation, simpler retrofits, and reliable alignment with existing systems, reducing engineering effort and commissioning time. Availability of CAD models and an Installation Guide (PDF) accelerates design integration, minimizes errors, and supports accurate tolerance planning during system integration. In practice, these features translate to lower total cost of ownership and easier ongoing maintenance in demanding industrial environments.

Get a Quick Quote for a Norgren QA/8100/51/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8100/51/200?

Enquire Now

FAQs

QA/8100/51/200 uses standard Norgren mounting patterns and accepts common end-plate and side-mount configurations. When planning a retrofit, verify alignment with existing interfaces and ensure fasteners match the mounting holes and tolerances specified in the Installation Guide to minimize rework and ensure repeatable positioning.

Consult the Installation Guide (PDF) for exact pressure and air quality guidance. In typical industrial practice, use clean, dry compressed air with proper filtration and a regulator to maintain stable pressure within the system’s operating range. Ensure upstream components are compatible with the cylinder’s preload and cylinder bore tolerances to avoid seal wear and stick-slip.

Certification specifics should be confirmed in the official datasheet or by contacting the supplier. While CE marking, IP ratings, and SIL readiness are common considerations for industrial actuators, verify the exact certifications for this variant in the product documentation and installation guide before deployment in regulated environments.

Perform regular visual inspections for unusual wear or misalignment. Follow the lubrication and service intervals in the installation guide, and replace worn seals or guides promptly. Maintain clean, dry air to minimize abrasion, and verify alignment with mating components during periodic PM cycles to preserve smooth, repeatable motion.

CAD assets accompanying the QA/8100/51/200 model enable engineers to accurately model clearances, mounting interfaces, and stroke envelopes within their assemblies. Use the CAD download to validate fitment, run interference checks, and streamline the component selection process, reducing design time and errors during integration.