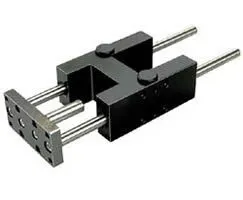

Norgren QA/8100/51/250 Guide Block - 100 mm Bore

Part Number: QA/8100/51/250

Quick Summary

Norgren QA/8100/51/250 guide block delivers precise linear guidance for pneumatic automation in manufacturing environments. Engineers often confront misalignment and wear during long-stroke cycles, which can cause drift, reduced repeatability, and downtime. In this class of components, CE conformity, IP-rated protection, and SIL-ready integration are common and help underpin safe, compliant operation in demanding facilities. This unit aligns with standard mounting patterns and existing Norgren actuators, enabling straightforward installation and reliable, repeatable strokes. The combination of robust plain bearing guidance and standard interfaces supports faster line commissioning and lower total cost of ownership, while maintaining high assembly throughput.

Product Information

Cylinder diameter

100 mm

Brand

IMI Norgren

Feature: 100 mm bore and 250 mm stroke provide ample travel for long-stroke applications, improving positioning flexibility and reducing the need for auxiliary guiding. Business Impact: Enables simpler layouts and fewer mid-stroke adjustments, driving higher line throughput and lower maintenance costs. Application: Ideal for automated material handling and precision positioning in assembly lines. Feature: Plain bearing style guide block reduces friction and wear, lowering operating costs. Business Impact: Extends service intervals and improves lifecycle cost, supporting predictable uptime. Application: Continuous operation in harsh environments typical of automation and control systems. Feature: Compatibility with standard mounting patterns and Norgren actuators streamlines installation. Business Impact: Faster commissioning and reduced installation risk, shortening time-to-line start. Application: Retrofit projects and new line builds in industrial facilities. Feature: CAD assets and installation guidance available for quick integration. Business Impact: Reduces engineering hours and design errors, ensuring repeatable results. Application: Early-stage design reviews and procurement coordination for pneumatic systems.

Get a Quick Quote for a Norgren QA/8100/51/250

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8100/51/250?

Enquire Now

FAQs

Begin by validating mounting pattern compatibility with your existing cylinder. Align the guide block inline with the cylinder axis, secure using the recommended end blocks or mounting brackets, and verify travel clearance. Consult the CAD download and Installation Guide for exact torque specs and sequence to ensure smooth, repeatable strokes.

With a 100 mm bore and 250 mm stroke, you gain substantial travel while maintaining stable guidance through a plain bearing design. Expect improved repeatability, reduced drift, and longer service intervals when assembled in a properly supported system. Regular inspection of alignment and lubrication per the Installation Guide will sustain optimal performance.

Yes, when paired with compatible actuators and mounting hardware, the QA/8100/51/250 provides reliable linear guidance for long-stroke pick-and-place operations. Its robust interface compatibility and straightforward installation support rapid line changeovers, while the 100 mm bore helps manage substantial payloads with consistent repeatability.

In line with industry norms for pneumatic components, CE conformity and IP-rated protection are commonly anticipated for this class, with SIL readiness achievable through system design. Please refer to the Installation Guide and product documentation for the exact ratings and any system-level safety requirements.

Users benefit from easier commissioning, longer service intervals, and lower downtime due to reliable alignment and reduced wear. Access CAD files and the Installation Guide to speed up design, procurement, and installation, delivering faster time-to-first-run and lower total cost of ownership across continuous production lines.