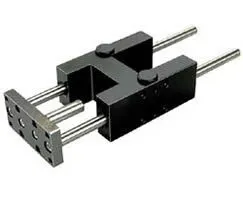

Norgren QA/8100/51/320 Guide Block - 320 mm Stroke

Part Number: QA/8100/51/320

Quick Summary

QA/8100/51/320 guide block delivers precise linear motion for automated tooling and pick-and-place systems. Engineers often contend with misalignment, installation complexity, and downtime when upgrading cylinders. Designed to meet common industry standards, available CE-compliant options and region-specific IP ratings help assure regulatory and environmental compliance. With IMI Norgren compatibility and a robust plain bearing design, installation is straightforward and service intervals are extended, lowering maintenance costs. Using the 100 mm bore foundation and a 320 mm stroke, the unit achieves predictable travel and repeatability, supporting higher throughput. Reduced cycle times translate to lower unit costs and faster ROI across manufacturing lines.

Product Information

Cylinder diameter

100 mm

Brand

IMI Norgren

Feature: 100 mm bore and 320 mm stroke in a guide block configuration provide a stable, repeatable travel path. Business Impact: Enhances positional accuracy and reduces backlash, translating into more consistent part handling and reduced scrap. Application: Ideal for automated assembly lines and precision pick-and-place tasks where repeatable motion matters. Feature: Plain bearing guidance delivers smooth, low-friction travel with durable wear characteristics. Business Impact: Extends component life and lowers maintenance frequency, reducing downtime and total cost of ownership. Application: Long-running cycle operations in packaging and material handling. Feature: Availability of CAD data and Installation Guide (PDF) accelerates deployment. Business Impact: Shortens commissioning time, minimizes misassembly, and supports rapid supplier onboarding. Application: OEM integration and retrofit projects across existing line equipment. Feature: IMI Norgren compatibility ensures plug-and-play integration with standard systems. Business Impact: Faster installation, fewer custom adapters, and lower SKU complexity. Application: Retrofitting legacy automation or scaling lines with compatible hardware. Feature: Certification-readiness and regional compliance options (CE, IP where applicable) help meet regulatory requirements. Business Impact: Reduces risk in regulated environments and simplifies customer qualification processes. Application: Industrial machinery, robotics, and compliant manufacturing setups. Feature: Rugged construction and compatibility with standard components support predictable maintenance cycles. Business Impact: Decreases unplanned downtime and improves overall equipment effectiveness (OEE). Application: Continuous operation environments in automotive and electronics manufacturing.

Get a Quick Quote for a Norgren QA/8100/51/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8100/51/320?

Enquire Now

FAQs

The QA/8100/51/320 guide block provides precise linear motion for automated tooling, assembly, and pick-and-place systems. With a 100 mm bore and 320 mm stroke, it supports repeatable travel on standard automation platforms, delivering improved positioning accuracy and consistent performance in high-cycle applications.

Yes. The guide block is designed around a 100 mm bore foundation and is compatible with IMI Norgren cylinder systems. This compatibility enables straightforward mounting, reduces the need for custom adapters, and supports quick upgrades or retrofits on existing lines.

For best results, ensure precise alignment of the guide block with the mating guide rail, follow torque specifications in the Installation Guide, and keep the bore clear of contaminants. Use the CAD data for correct mounting patterns, and perform regular inspection and lubrication as part of a standard maintenance routine.

Regional certifications vary by market. The QA/8100/51/320 line is designed to support CE-compliant configurations and IP-rated variants where applicable. Always verify the specific model’s certification status with your distributor or the data sheet to ensure compliance for your application region.

The plain bearing guide and robust assembly reduce wear and downtime, extending service intervals and improving machine availability. Combined with easy installation and readily available CAD guides, this leads to lower maintenance costs, faster cycle times, and a quicker return on investment in automated production lines.