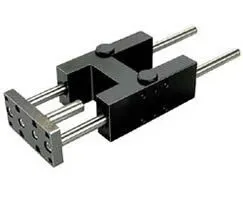

Norgren QA/8100/51/400 Guide block plain bearing - 100 mm bore

Part Number: QA/8100/51/400

Quick Summary

Norgren QA/8100/51/400 is a guide block pneumatic cylinder delivering precise, repeatable linear motion for automated systems. Engineers often contend with wear in plain bearings and inconsistent stroke under load; this design minimizes backlash and reduces maintenance in demanding applications. Typical certifications to verify for cylinders of this type include CE marking, IP ratings, and SIL readiness depending on configuration; always consult the official datasheet and the installation guide for specifics. For procurement teams, rapid integration is supported by CAD downloads and clear mounting instructions, enabling faster deployment, easier maintenance planning, and improved overall system reliability. Partners gain confidence from documented compatibility and a simplified upgrade path.

Product Information

Cylinder diameter

100 mm

Brand

IMI Norgren

Feature: a 100 mm bore provides robust load capacity and improved cylinder stiffness for consistent thrust. Business Impact: reduced deflection and seal wear translate to longer cycle life and lower maintenance costs. Application: ideal for material handling, automated assembly, and packaging lines where precision and repeatability matter. Feature: a 400 mm stroke offers ample travel for longer reach and fewer cylinder changes in line setups. Business Impact: lowers capital expenditure and simplifies inventory management across production cells. Application: suited for gantry, pick-and-place, and end-of-line actuation where space permits extended travel. Feature: guide block plain bearing design minimizes friction and backlash. Business Impact: delivers repeatable motion with low wear, improving cycle consistency and reducing preventive maintenance. Application: ideal for linear guides in automation frames and assembly stations. Feature: CAD and installation documentation available. Business Impact: accelerates engineering workflows and reduces integration risk. Application: rapid onboarding for OEMs and integrators deploying retrofits or new lines. Feature: robust build with compatibility to Norgren accessories. Business Impact: easier mounting, faster commissioning, and streamlined maintenance. Application: retrofit projects and new installations within automation and control systems.

Get a Quick Quote for a Norgren QA/8100/51/400

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8100/51/400?

Enquire Now

FAQs

This model supports standard mounting patterns compatible with Norgren accessories, including flange and clevis-style mounts. When planning integration, refer to the CAD models and the installation guide to confirm fitment, fastener sizes, and alignment practices. Practical guidance helps ensure repeatable positioning and fast commissioning on automation lines.

QA/8100/51/400 features a 100 mm bore and a 400 mm stroke, enabling greater load capacity and extended travel compared with smaller cylinders. This combination supports higher stiffness, reduced deflection, and longer service life in repetitive pick-and-place and material-handling tasks, while preserving compact footprint in automated cells.

Yes. The 100 mm bore and 400 mm stroke, coupled with the guide block plain bearing design, provide precise, repeatable motion with low friction and minimal backlash. This makes it well-suited for high-volume assembly lines, packaging, and pick-and-place applications where consistent cycle times and predictable behavior are critical.

Key certifications to verify for pneumatic cylinders of this type include CE marking for European compliance, IP ratings for environmental protection, and SIL readiness where safety-related applications are involved. Check the official datasheet and the installation guide for configuration-specific approvals and testing requirements before deployment in safety-critical systems.

CAD downloads and the Installation Guide (PDF) are provided through the product resources. Use the CAD link for model geometry and mounting references, and consult the Installation Guide for step-by-step mounting, alignment, and maintenance procedures to ensure a smooth retrofit or greenfield installation.