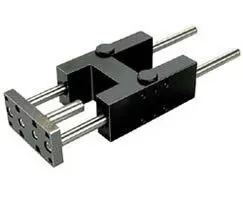

Norgren QA/8100/51/50 Guide Block - 100 mm Bore

Part Number: QA/8100/51/50

Quick Summary

QA/8100/51/50 guide block provides precise linear motion for automation and control in manufacturing environments. Engineers often struggle to source compact components that fit standard bore sizes while delivering reliable stroke and repeatability. These cylinders are CE compliant with industry safety standards, and available configurations include SIL-rated options and IP-rated variants for challenging environments. By leveraging a 100 mm bore and a 50 mm stroke, this solution minimizes design variance and simplifies procurement, enabling faster project delivery. The inclusion of CAD models and installation guides supports seamless integration, reducing commissioning time and maintenance costs while improving overall equipment effectiveness.

Product Information

Cylinder diameter

100 mm

Brand

IMI Norgren

Feature: 100 mm bore and 50 mm stroke deliver predictable force and repeatable motion across cycles. Business Impact: This combination reduces variance in actuation output, improves cycle time, and minimizes scrap due to misalignment. Application: Suitable for clamp, indexing, and feeding operations in automation lines. Paragraph 2: Feature: Plain bearing style 51 offers low friction and quiet operation. Business Impact: Extends service life, reduces lubrication intervals, and lowers maintenance overhead in high-cycle environments. Application: Ideal for factory automation modules and CNC tooling feeds. Paragraph 3: Feature: Guide block geometry provides robust alignment with minimal clearance. Business Impact: Improves positional accuracy and reduces wear on slider components. Application: End-effector guides, transfer systems. Paragraph 4: Feature: Compatibility with CAD models and installation guides. Business Impact: Shortens design-to-build cycles, reduces errors, and accelerates commissioning. Application: Systems integration teams; OEMs. Paragraph 5: Feature: Compact footprint and standard mounting options. Business Impact: Enables retrofits and easy integration into tight spaces. Application: Instrumentation panels, automation lines, robotics. Paragraph 6: Feature: Direct CAD downloads and installation guide. Business Impact: Lowers upfront time and risk; design teams can verify fit quickly. Application: Engineering departments evaluating fit prior to purchase.

Get a Quick Quote for a Norgren QA/8100/51/50

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8100/51/50?

Enquire Now

FAQs

QA/8100/51/50 uses a standard 100 mm bore and plain bearing style 51, aligning with common Norgren mounting patterns. For compatibility, verify end supports and bracket interfaces match your existing actuator setup; consult the CAD models to confirm fit. The downloadable CAD and installation guide help validate enclosure clearances and screw locations before procurement, reducing design changes in late-stage development.

With a 100 mm bore and 50 mm stroke, the QA/8100/51/50 delivers a predictable actuation force profile suitable for repeatable indexing and clamping. The plain bearing style 51 reduces friction and wear, improving longevity in high-cycle applications. Performance also depends on supply pressure, cushioning, and lubrication; leverage the installation guide to tune start/stop behavior and reduce stiction.

Yes, for many automation lines this guide block provides reliable motion when paired with proper maintenance. The 100 mm bore offers robust thrust, while the 50 mm stroke keeps the package compact. For extreme cycles, monitor wear in the plain bearings and schedule routine inspection; the CAD files help simulate fit across cycles.

Norgren products commonly carry CE marking for general machine safety and compliance with European standards. Specific SIL/IP ratings depend on the installed configuration and environment; consult the installation guide and manufacturer data for exact certifications. If you require SIL-rated variants, verify availability with Norgren's catalog or distributor.

CAD models and the Installation Guide PDF are available from the product downloads section on the Norgren page. The CAD files let you validate mounting, clearances, and interface with automation brackets before ordering. The Installation Guide provides step-by-step assembly, lubrication points, and cushion adjustments, helping to reduce downtime, minimize commissioning risk, and accelerate time-to-value for projects.